Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

Closed Cell EPDM Foam Sponge - Manufacturer

Our closed cell EPDM form sponge is a high quality closed cell material that is easy to form an airtight and waterproof seal. Excellent UV and ozone resistance, ideal for outdoor sealing applications. In addition to providing excellent weather resistance, closed cell EPDM also provides good flexibility, Tensile Strength and recovery properties. The closed-cell construction provides excellent heat sealing, prevents the build-up of bacteria and mold, and handles high-pressure sealing applications at better speeds, making them more durable, which in turn increases the material's life expectancy in demanding applications.

The price of closed cell EPDM foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

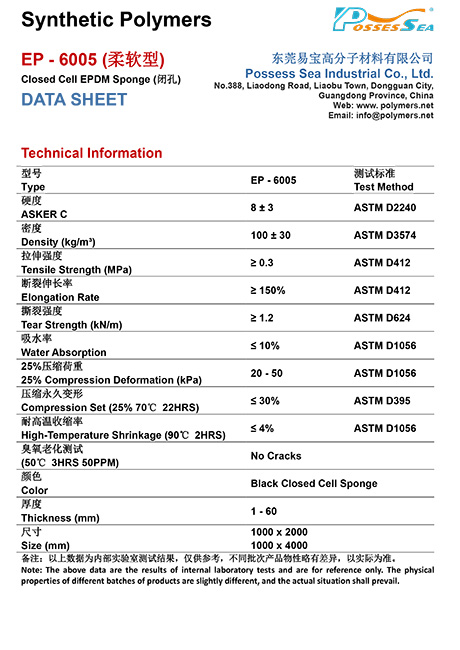

Closed Cell EPDM Foam Sponge - EP-6005

Explain: EP-6005 is a special type of ultra-low hardness and ultra-low density soft closed cell EPDM foam sponge.

Color: Black.

Size (mm): 1000 X 2000、1000 X 4000.

Hardness (ASKER C): 8 ± 3.

Density (kg/m³): 100 ± 30.

Tensile Strength (MPa): ≥ 0.3.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 1.2.

Water Absorption: ≤ 10%.

25% Compression Deformation (kPa): 20 - 50.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Similar to INOAC E-4070, colors and specifications can be developed and customized according to customer requirements.

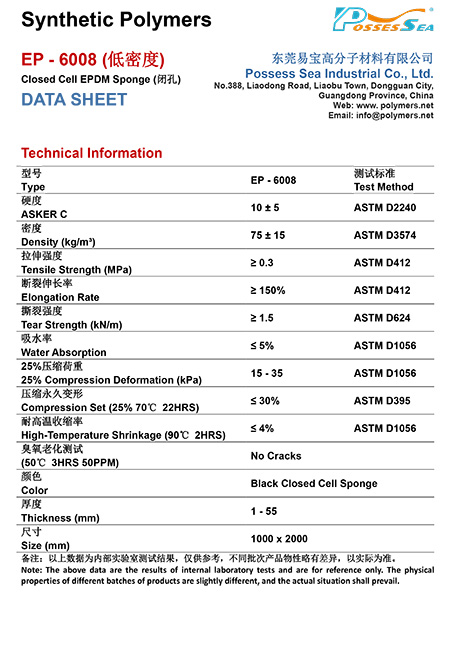

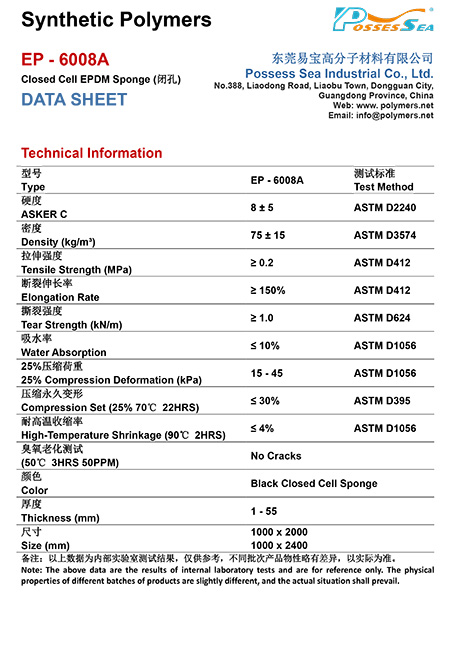

Closed Cell EPDM Foam Sponge - EP-6008

Explain: EP-6008 is a special type of ultra-low hardness and ultra-low density soft closed cell EPDM foam sponge.

| Type | EP-6008 | EP-6008A |

| Color | Black | |

| Size (mm) | 1000 X 2000 | |

| Hardness (ASKER C) | 10 ± 5 | 8 ± 5 |

| Density (kg/m³) | 75 ± 15 | |

| Tensile Strength (MPa) | ≥ 0.3 | ≥ 0.2 |

| Elongation Rate | ≥ 150% | |

| Tear Strength (kN/m) | ≥ 1.5 | ≥ 1.0 |

| Water Absorption | ≤ 5% | ≤ 10% |

| 25% Compression Deformation (kPa) | 15 - 35 | 15 - 35 |

| Compression Set (25% 70℃ 22HRS) |

≤ 30% | |

| High-Temperature Shrinkage (90℃ 2HRS) | ≤ 4% | |

Note: Similar to INOAC E-4088, colors and specifications can be developed and customized according to customer requirements.

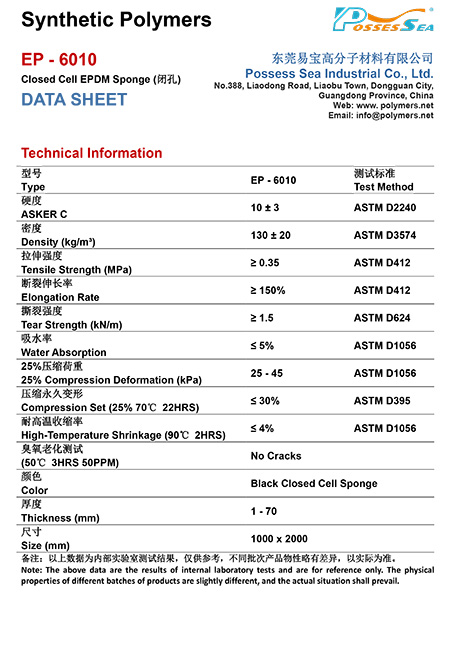

Closed Cell EPDM Foam Sponge - EP-6010

Explain: EP-6010 is a special type of low hardness and low density closed cell EPDM foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 10 ± 3.

Density (kg/m³): 130 ± 20.

Tensile Strength (MPa): ≥ 0.35.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 1.5.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 25 - 45.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Similar to INOAC E-4188, colors and specifications can be developed and customized according to customer requirements.

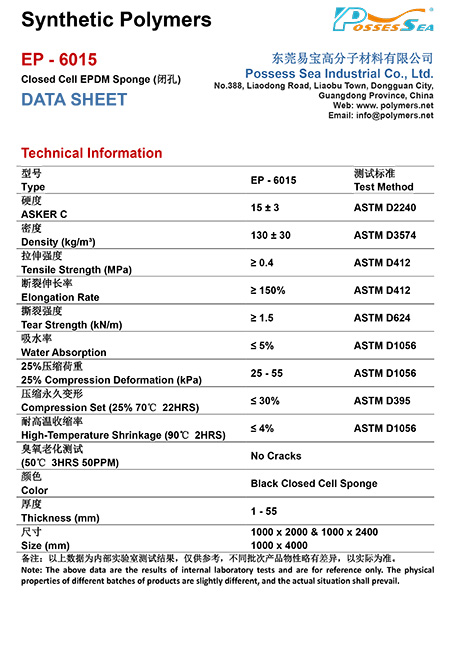

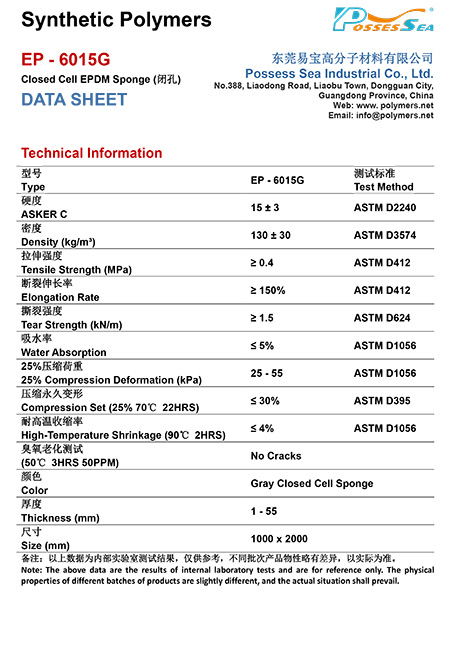

Closed Cell EPDM Foam Sponge - EP-6015

Explain: EP-6015 is a conventional low hardness and low density closed cell EPDM foam sponge, available in black and gray, suitable for sealing applications of automotive window glass.

| Type | EP-6015 | EP-6015G |

| Color | Black | Gray |

| Size (mm) | 1000 X 2000 1000 X 4000 |

|

| Hardness (ASKER C) | 15 ± 3 | |

| Density (kg/m³) | 130 ± 30 | |

| Tensile Strength (MPa) | ≥ 0.4 | |

| Elongation Rate | ≥ 150% | |

| Tear Strength (kN/m) | ≥ 1.5 | |

| Water Absorption | ≤ 5% | |

| 25% Compression Deformation (kPa) | 25 - 55 | |

| Compression Set (25% 70℃ 22HRS) |

≤ 30% | |

| High-Temperature Shrinkage (90℃ 2HRS) | ≤ 4% | |

Note: Similar to INOAC E-4108, colors and specifications can be developed and customized according to customer requirements.

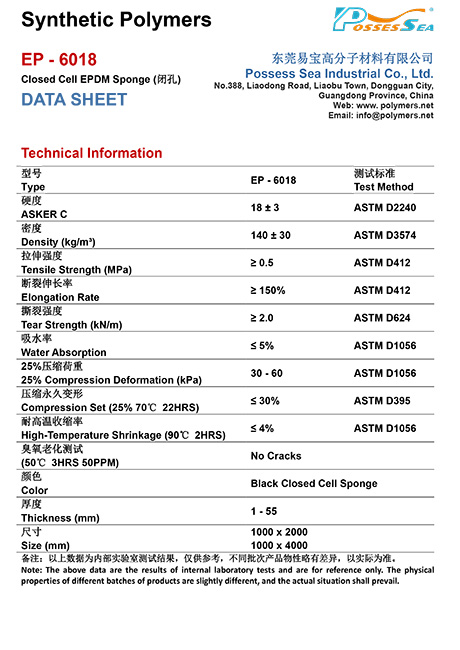

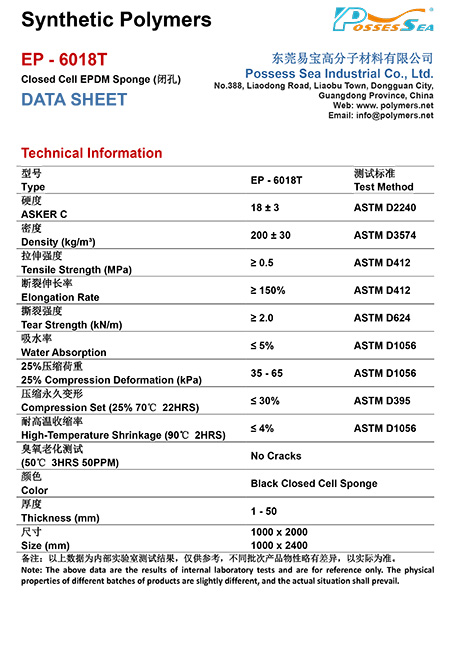

Closed Cell EPDM Foam Sponge - EP-6018

Explain: EP-6018 is the density closed cell EPDM foam sponge in the regular medium hardness, and the sub-model EP-6018T is a special heavy model with high density, which is suitable for the sealing of automobile window glass.

| Type | EP-6018 | EP-6018T |

| Color | Black | |

| Size (mm) | 1000 X 2000 1000 X 4000 |

1000 X 2000 |

| Hardness (ASKER C) | 18 ± 3 | |

| Density (kg/m³) | 140 ± 30 | 200 ± 30 |

| Tensile Strength (MPa) | ≥ 0.5 | |

| Elongation Rate | ≥ 150% | |

| Tear Strength (kN/m) | ≥ 2.0 | |

| Water Absorption | ≤ 5% | |

| 25% Compression Deformation (kPa) | 30 - 60 | 35 - 65 |

| Compression Set (25% 70℃ 22HRS) |

≤ 30% | |

| High-Temperature Shrinkage (90℃ 2HRS) | ≤ 4% | |

Note: Colors and specifications can be developed and customized according to customer requirements.

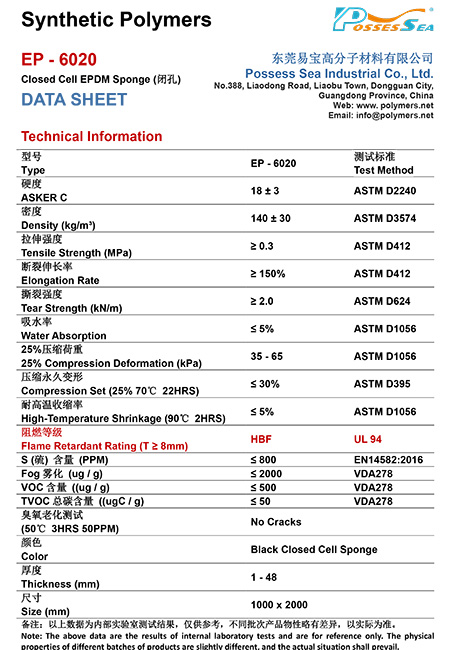

Closed Cell EPDM Foam Sponge - EP-6020

Explain: EP-6020 is the medium hardness and density low-sulfur flame-retardant closed cell EPDM foam sponge, which meets the VDA278 standard and is suitable for the sealing of automobile lights and window glass.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 18 ± 3.

Density (kg/m³): 140 ± 30.

Tensile Strength (MPa): ≥ 0.3.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 2.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 35 - 65.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 5%.

Flame Retardant Rating (UL 94): ≥8mm HBF.

Note: Similar to INOAC E-4338, colors and specifications can be developed and customized according to customer requirements.

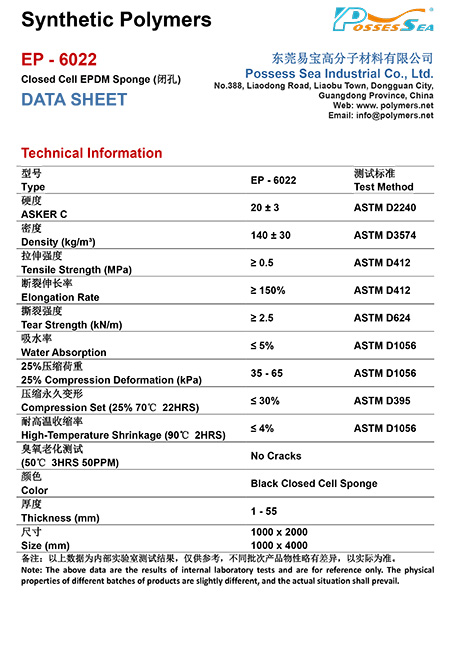

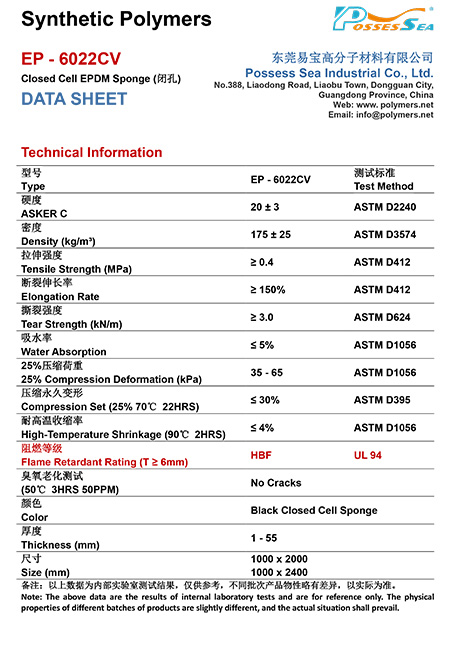

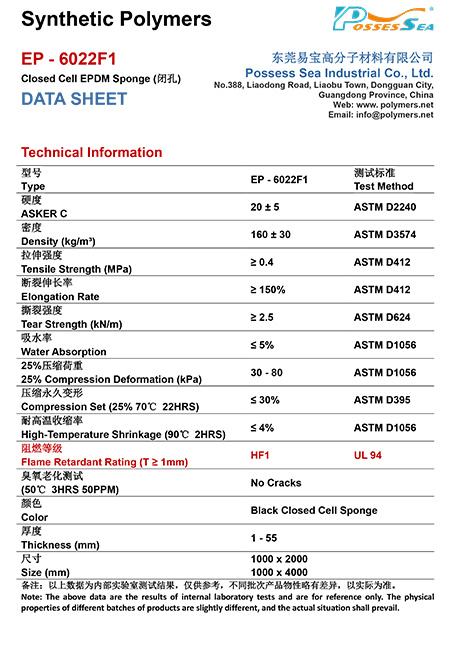

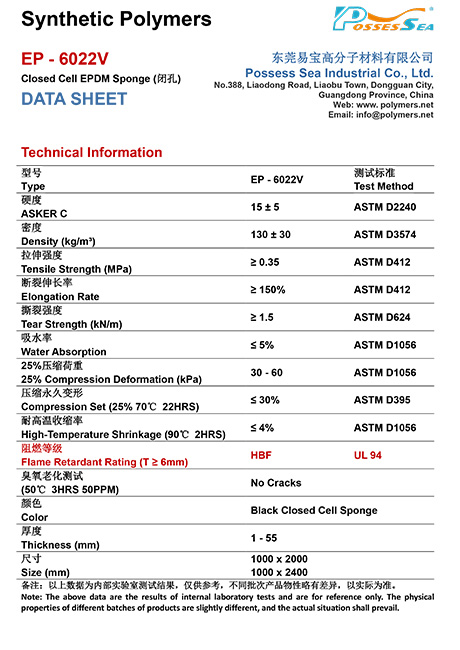

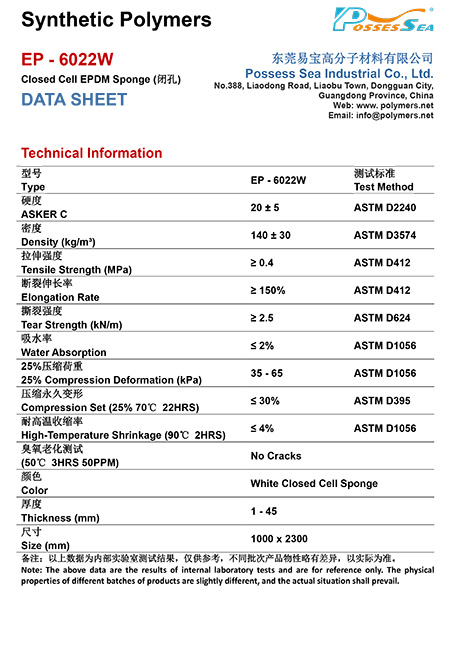

Closed Cell EPDM Foam Sponge - EP-6022

Explain: EP-6022 is the medium hardness and density closed cell EPDM foam sponge, which is available in black and white. There are also several special models with low VOC, flame retardant and high density sub-models to choose from.

| Type | EP-6022 | EP-6022W | EP-6022V | EP-6022CV | EP-6022F1 |

| Color | Black | White | Black | ||

| Size (mm) | 1000 X 2000 1000 X 4000 |

1000 X 2300 | 1000 X 2000 1000 X 4000 |

||

| Hardness (ASKER C) |

20 ± 3 | 20 ± 5 | 15 ± 5 | 20 ± 3 | 20 ± 5 |

| Density (kg/m³) | 140 ± 30 | 130 ± 30 | 175 ± 25 | 160 ± 30 | |

| Tensile Strength (MPa) | ≥ 0.5 | ≥ 0.4 | ≥ 0.35 | ≥ 0.4 | |

| Tear Strength (kN/m) | ≥ 2.5 | ≥ 1.5 | ≥ 3.0 | ≥ 2.5 | |

| 25% Compression Deformation (kPa) | 35 - 65 | 30 - 60 | 35 - 65 | 30 - 80 | |

| Flame Retardant Rating (UL 94) |

/ | ≥6mm HBF | ≥1mm HF1 | ||

Note: Similar to INOAC E-4388 / E-4390, colors and specifications can be developed and customized according to customer requirements.

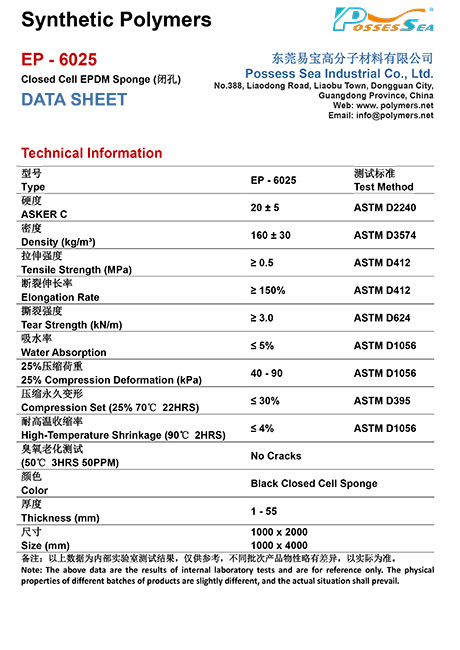

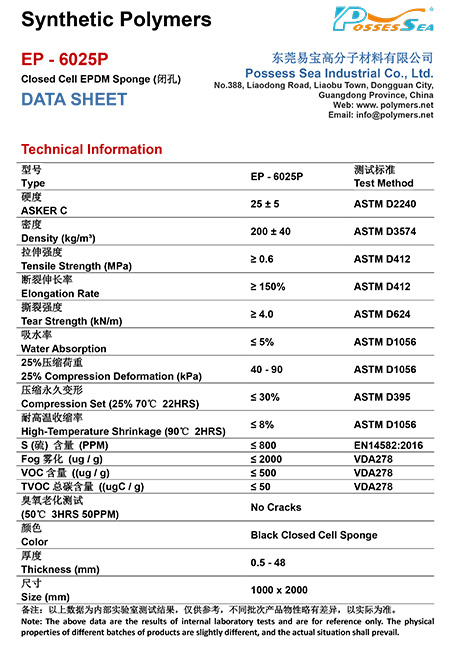

Closed Cell EPDM Foam Sponge - EP-6025

Explain: EP-6025 is the conventional medium hardness and high density low sulfur closed cell EPDM foam sponge, which conforms to the VDA278 standard.

| Type | EP-6025 | EP-6025P |

| Color | Black | |

| Size (mm) | 1000 X 2000 | |

| Hardness (ASKER C) | 20 ± 5 | 25 ± 5 |

| Density (kg/m³) | 160 ± 30 | 200 ± 40 |

| Tensile Strength (MPa) | ≥ 0.5 | ≥ 0.6 |

| Elongation Rate | ≥ 150% | |

| Tear Strength (kN/m) | ≥ 3.0 | ≥ 4.0 |

| Water Absorption | ≤ 5% | |

| 25% Compression Deformation (kPa) | 40 - 90 | |

| Compression Set (25% 70℃ 22HRS) |

≤ 30% | |

| High-Temperature Shrinkage (90℃ 2HRS) | ≤ 4% | ≤ 8% |

Note: Colors and specifications can be developed and customized according to customer requirements.

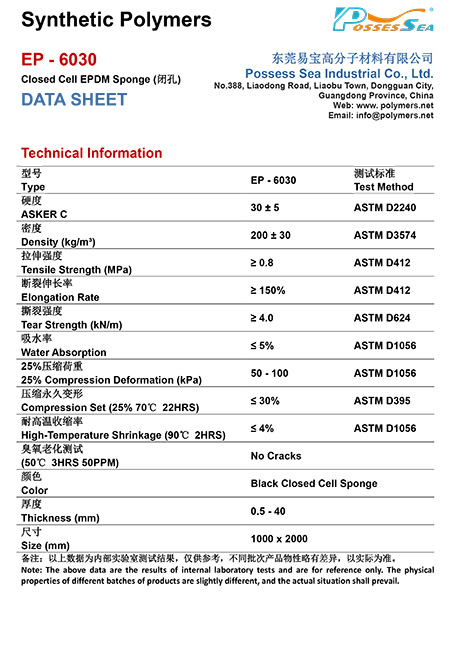

Closed Cell EPDM Foam Sponge - EP-6030

Explain: EP-6030 is a special type of closed cell EPDM foam sponge with high hardness and density.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 30 ± 5.

Density (kg/m³): 200 ± 30.

Tensile Strength (MPa): ≥ 0.8.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 4.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 50 - 100.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Similar to INOAC E-4308, colors and specifications can be developed and customized according to customer requirements.

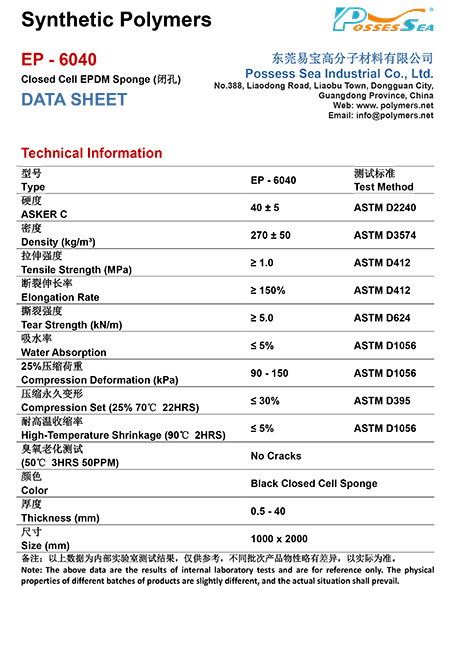

Closed Cell EPDM Foam Sponge - EP-6040

Explain: EP-6040 is a special type of closed cell EPDM foam sponge with high hardness and density.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 40 ± 5.

Density (kg/m³): 270 ± 50.

Tensile Strength (MPa): ≥ 1.0.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 5.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 90 - 150.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 5%.

Note: Similar to INOAC E-4408, colors and specifications can be developed and customized according to customer requirements.

List of Physical Properties of Closed Cell EPDM Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| EP-6005 | 8 ± 3 | 100 ± 30 | ≥ 0.3 | 20 - 50 | / | 1000 x 2000 1000 x 4000 |

| EP-6008 | 10 ± 5 | 75 ± 15 | ≥ 0.3 | 15 - 35 | / | 1000 x 2000 |

| EP-6008A | 8 ± 5 | 75 ± 15 | ≥ 0.2 | 15 - 45 | / | 1000 x 2000 |

| EP-6010 | 10 ± 3 | 130 ± 20 | ≥ 0.35 | 25 - 45 | / | 1000 x 2000 |

| EP-6015 | 15 ± 3 | 130 ± 30 | ≥ 0.4 | 25 - 55 | / | 1000 x 2000 1000 x 4000 |

| EP-6015G | 15 ± 3 | 130 ± 30 | ≥ 0.4 | 25 - 55 | / | 1000 x 2000 |

| EP-6018 | 18 ± 3 | 140 ± 30 | ≥ 0.5 | 30 - 60 | / | 1000 x 2000 1000 x 4000 |

| EP-6018T | 18 ± 3 | 200 ± 30 | ≥ 0.5 | 35 - 65 | / | 1000 x 2000 |

| EP-6020 | 18 ± 3 | 140 ± 30 | ≥ 0.3 | 35 - 65 | HBF | 1000 x 2000 |

| EP-6022 | 20 ± 3 | 140 ± 30 | ≥ 0.5 | 35 - 65 | / | 1000 x 2000 1000 x 4000 |

| EP-6022W | 20 ± 5 | 140 ± 30 | ≥ 0.4 | 35 - 65 | / | 1000 x 2300 |

| EP-6022V | 15 ± 5 | 130 ± 30 | ≥ 0.35 | 30 - 60 | HBF | 1000 x 2000 1000 x 4000 |

| EP-6022CV | 20 ± 3 | 175 ± 25 | ≥ 0.4 | 35 - 65 | HBF | 1000 x 2000 1000 x 4000 |

| EP-6022F1 | 20 ± 5 | 160 ± 30 | ≥ 0.4 | 30 - 80 | HF1 | 1000 x 2000 1000 x 4000 |

| EP-6025 | 20 ± 5 | 160 ± 30 | ≥ 0.5 | 40 - 90 | / | 1000 x 2000 |

| EP-6025P | 25 ± 5 | 200 ± 40 | ≥ 0.6 | 40 - 90 | / | 1000 x 2000 |

| EP-6030 | 30 ± 5 | 200 ± 30 | ≥ 0.8 | 50 - 100 | / | 1000 x 2000 |

| EP-6040 | 40 ± 5 | 270 ± 50 | ≥ 1.0 | 90 - 150 | / | 1000 x 2000 |

Explain: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

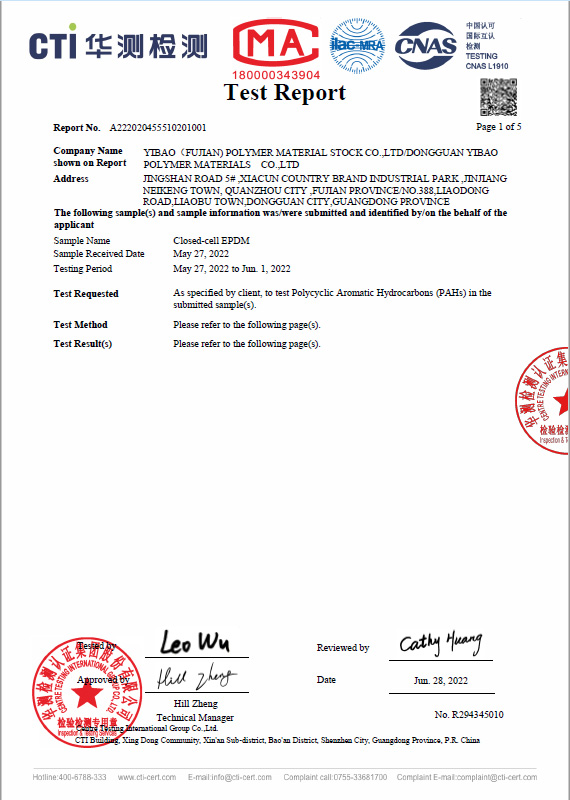

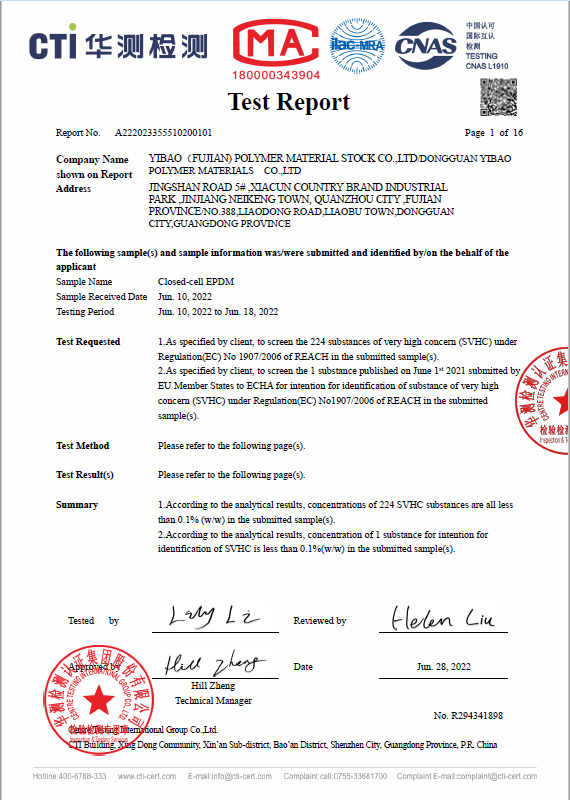

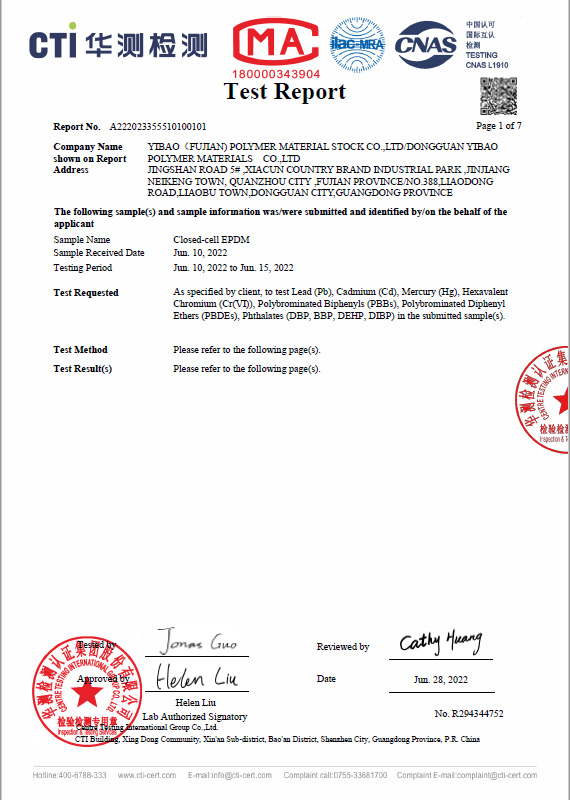

Closed Cell EPDM Foam Sponge CTI Test Report:

CTI PAHs Test Report

CTI REACH Test Report

CTI RoHS Test Report

Explain: Please contact sales representative for the complete test report.

Closed Cell EPDM Foam Sponge Can Fulfill The Below International Standards:

| PAHs | 15 substances (PAHs) for REACH Annex XVII Article 50 Amendment (Regulation (EC) No 1272/2013) |

| REACH (SVHC) | 224 + 1 Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 of REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| Sulfur-Free | Restriction of sulfur content - sulfur (S) - EN 14582:2016 |

| Halogen-Free | Restriction of halogen content - fluorine (F), chlorine (Cl), bromine (Br) and iodine (I) - EN 14582:2016 |