Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

Open Cell EPDM Foam Sponge - Manufacturer

Our open cell EPDM foam sponge is a versatile high performance sealing material. It offers many of the same properties as closed cell materials, including durability and resistance to weathering, UV light, aging and ozone. The open-cell structure gives it excellent recovery properties or resistance to Compression Set, capable of returning to its original shape after compression. When the pressure is released, the air pockets in its porous tissue return to their original shape, making them ideal for applications that require sealing or cushioning of irregular depths or uneven areas.

The price of open cell EPDM foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

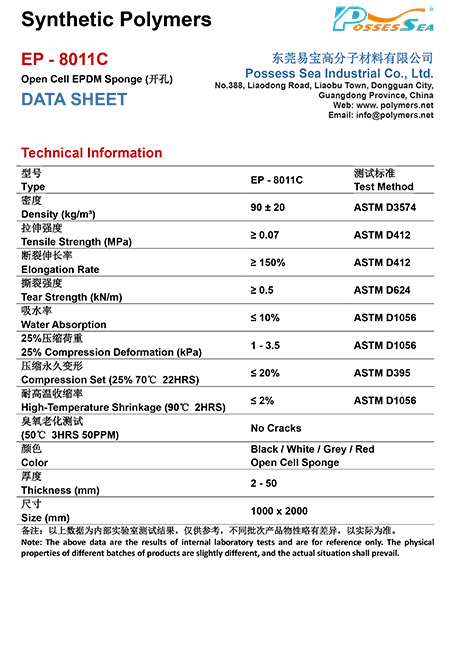

Open Cell EPDM Foam Sponge - EP-8011C

Explain: EP-8011C is the most commonly used open cell EPDM foam sponge, there are more than ten types of models, fine-pores, slow rebound, low VOC, low density, widely used in various fields.

Color: Black, white, gray, red.

Size (mm): 1000 X 2000.

| Type | Density (kg/m³) | Tensile Strength (MPa) | Feature |

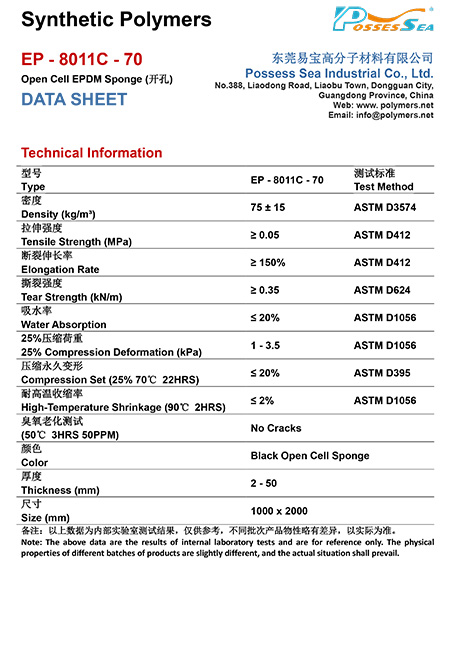

| EP-8011C-70 | 75 ± 15 | ≥ 0.05 | / |

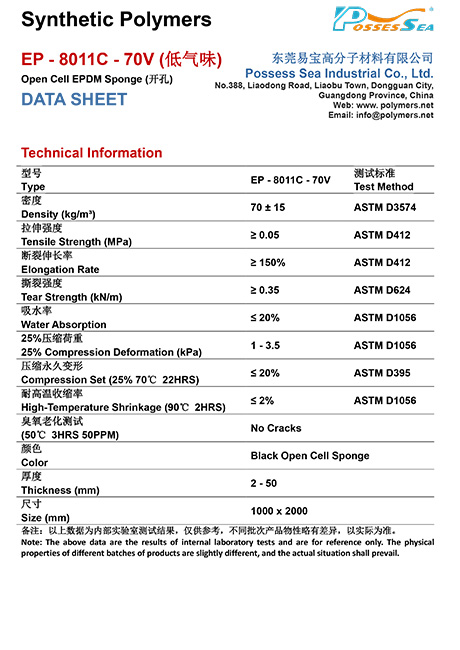

| EP-8011C-70V | 70 ± 15 | ≥ 0.05 | Low VOC, similar to EV-1000 |

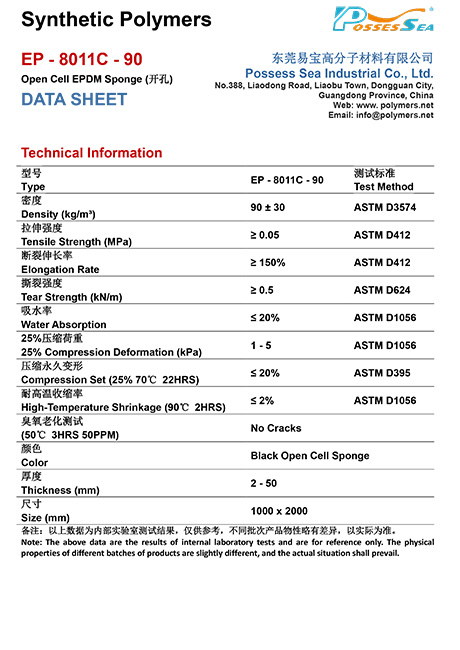

| EP-8011C-90 | 90 ± 30 | ≥ 0.05 | Similar to EV-1000 |

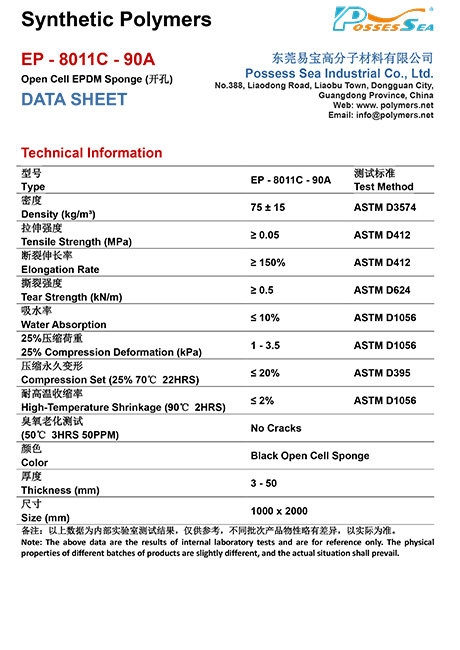

| EP-8011C-90A | 75 ± 15 | ≥ 0.05 | / |

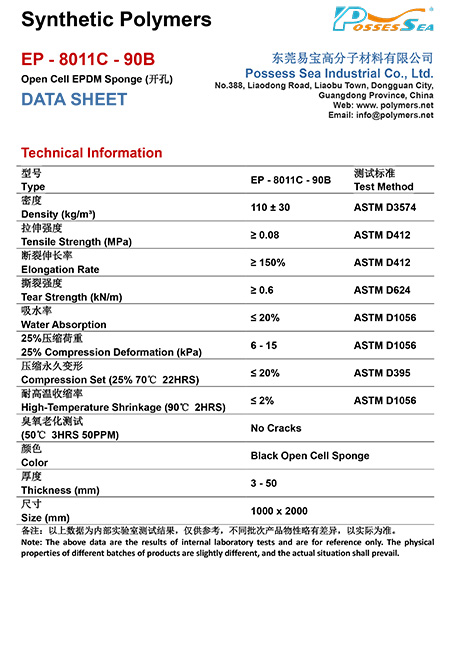

| EP-8011C-90B | 110 ± 30 | ≥ 0.08 | / |

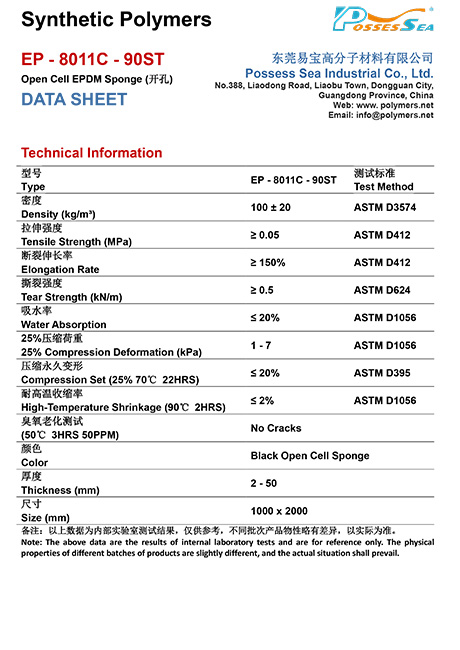

| EP-8011C-90ST | 100 ± 20 | ≥ 0.05 | / |

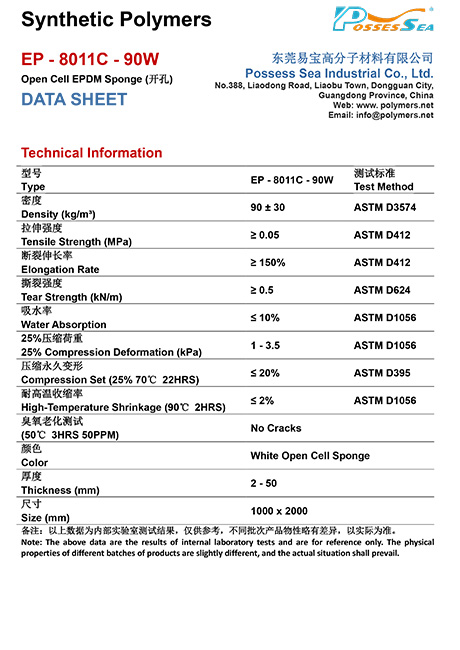

| EP-8011C-90W | 90 ± 30 | ≥ 0.05 | / |

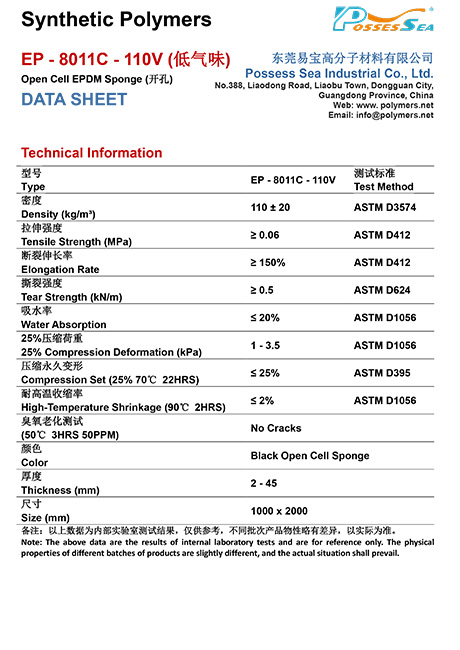

| EP-8011C-110V | 110 ± 20 | ≥ 0.06 | Low VOC, similar to EE-1000 |

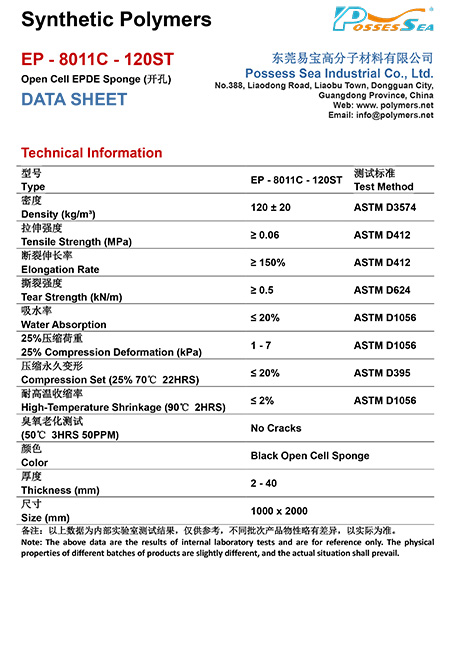

| EP-8011C-120ST | 120 ± 20 | ≥ 0.06 | / |

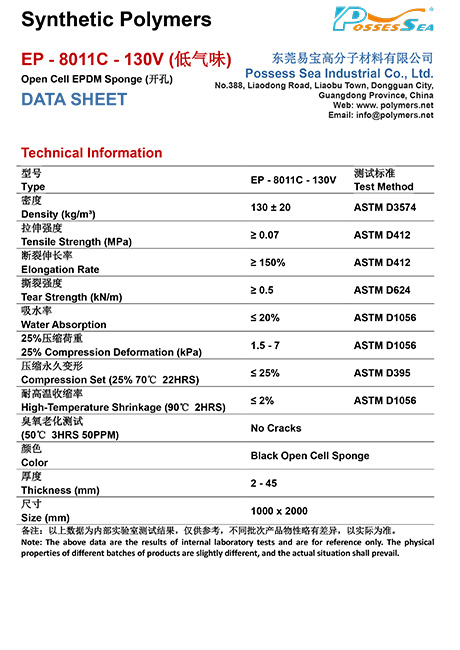

| EP-8011C-130V | 130 ± 20 | ≥ 0.07 | Low VOC, similar to E-685 |

Note: Colors and specifications can be developed and customized according to customer requirements.

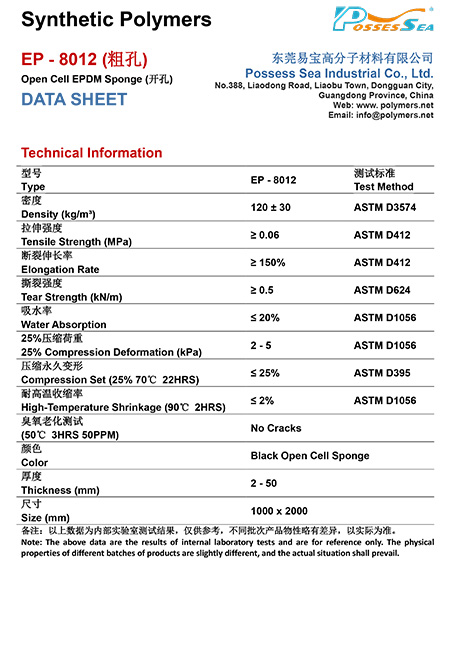

Open Cell EPDM Foam Sponge - EP-8012

Explain: EP-8012 is a coarse-pored open cell EPDM foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Density (kg/m³): 120 ± 30.

Tensile Strength (MPa): ≥ 0.06.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 0.5.

Water Absorption: ≤ 20%.

25% Compression Deformation (kPa): 2 - 5.

Compression Set (25% 70℃ 22HRS): ≤ 25%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 2%.

Feature: Similar to Bridgestone 730.

Note: Colors and specifications can be developed and customized according to customer requirements.

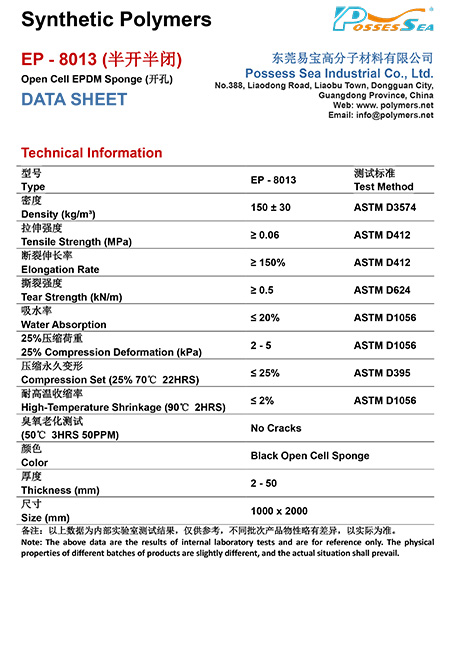

Open Cell EPDM Foam Sponge - EP-8013

Explain: EP-8013 is a semi-open and semi-closed high density EPDM foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Density (kg/m³): 150 ± 30.

Tensile Strength (MPa): ≥ 0.06.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 0.5.

Water Absorption: ≤ 20%.

25% Compression Deformation (kPa): 2 - 5.

Compression Set (25% 70℃ 22HRS): ≤ 25%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 2%.

Note: Colors and specifications can be developed and customized according to customer requirements.

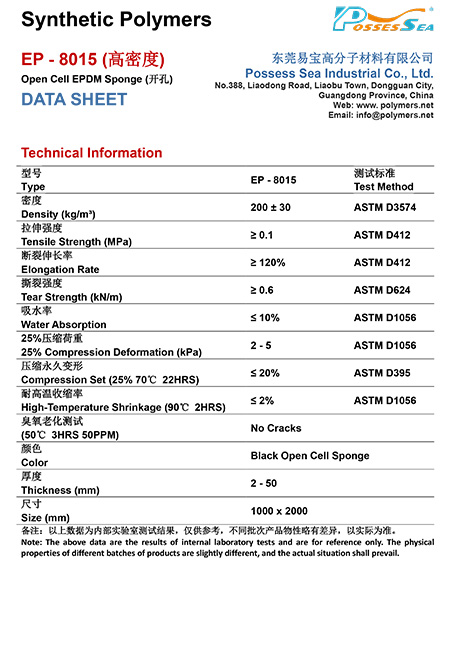

Open Cell EPDM Foam Sponge - EP-8015

Explain: EP-8015 is a open cell EPDM foam sponge with high density and coarse-pored.

Color: Black.

Size (mm): 1000 X 2000.

Density (kg/m³): 200 ± 30.

Tensile Strength (MPa): ≥ 0.1.

Elongation Rate: ≥ 120%.

Tear Strength (kN/m): ≥ 0.6.

Water Absorption: ≤ 10%.

25% Compression Deformation (kPa): 2 - 5.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 2%.

Note: Colors and specifications can be developed and customized according to customer requirements.

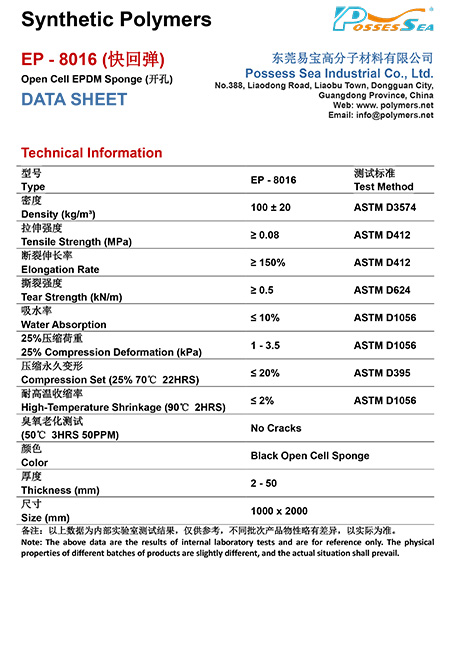

Open Cell EPDM Foam Sponge - EP-8016

Explain: EP-8016 is a open-cell EPDM foam sponge with fast rebound and fine-pored.

Color: Black.

Size (mm): 1000 X 2000.

Density (kg/m³): 100 ± 20.

Tensile Strength (MPa): ≥ 0.08.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 0.5.

Water Absorption: ≤ 10%.

25% Compression Deformation (kPa): 1 - 3.5.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 2%.

Feature: Suitable for robot suction cups.

Note: Colors and specifications can be developed and customized according to customer requirements.

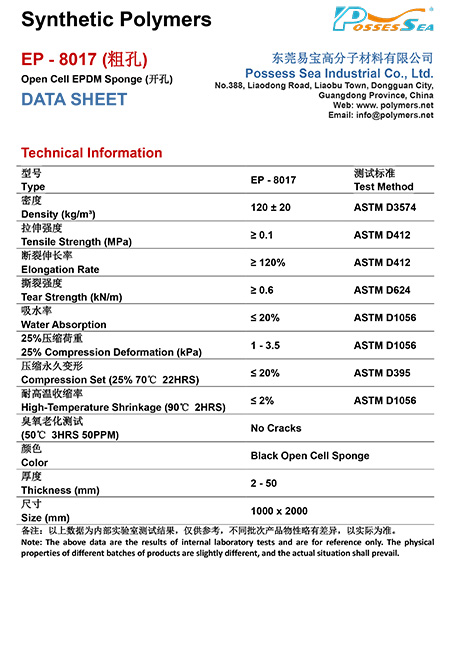

Open Cell EPDM Foam Sponge - EP-8017

Explain: EP-8017 is a coarse-pored EPDM foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Density (kg/m³): 120 ± 20.

Tensile Strength (MPa): ≥ 0.1.

Elongation Rate: ≥ 120%.

Tear Strength (kN/m): ≥ 0.6.

Water Absorption: ≤ 20%.

25% Compression Deformation (kPa): 1 - 3.5.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 2%.

Note: Colors and specifications can be developed and customized according to customer requirements.

List of Physical Properties of Open Cell EPDM Foam Sponge:

| Type | Density | Tensile Strength | Tear Strength | 25% Compression Deformation | Size |

| ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D624 (kN/m) |

ASTM D1056 (kPa) |

mm | |

| EP-8011C | 90 ± 20 | ≥ 0.07 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-70 | 75 ± 15 | ≥ 0.05 | ≥ 0.35 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-70V | 70 ± 15 | ≥ 0.05 | ≥ 0.35 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-90 | 90 ± 30 | ≥ 0.05 | ≥ 0.5 | 1 - 5 | 1000 x 2000 |

| EP-8011C-90A | 75 ± 15 | ≥ 0.05 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-90B | 110 ± 30 | ≥ 0.08 | ≥ 0.6 | 6 - 15 | 1000 x 2000 |

| EP-8011C-90ST | 100 ± 20 | ≥ 0.05 | ≥ 0.5 | 1 - 7 | 1000 x 2000 |

| EP-8011C-90W | 90 ± 30 | ≥ 0.05 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-110V | 110 ± 20 | ≥ 0.06 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-120ST | 120 ± 20 | ≥ 0.06 | ≥ 0.5 | 1 - 7 | 1000 x 2000 |

| EP-8011C-130V | 130 ± 20 | ≥ 0.07 | ≥ 0.5 | 1.5 - 7 | 1000 x 2000 |

| EP-8012 | 120 ± 30 | ≥ 0.06 | ≥ 0.5 | 2 - 5 | 1000 x 2000 |

| EP-8013 | 150 ± 30 | ≥ 0.06 | ≥ 0.5 | 2 - 5 | 1000 x 2000 |

| EP-8015 | 200 ± 30 | ≥ 0.1 | ≥ 0.6 | 2 - 5 | 1000 x 2000 |

| EP-8016 | 100 ± 20 | ≥ 0.08 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8017 | 120 ± 20 | ≥ 0.1 | ≥ 0.6 | 1 - 3.5 | 1000 x 2000 |

Note: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

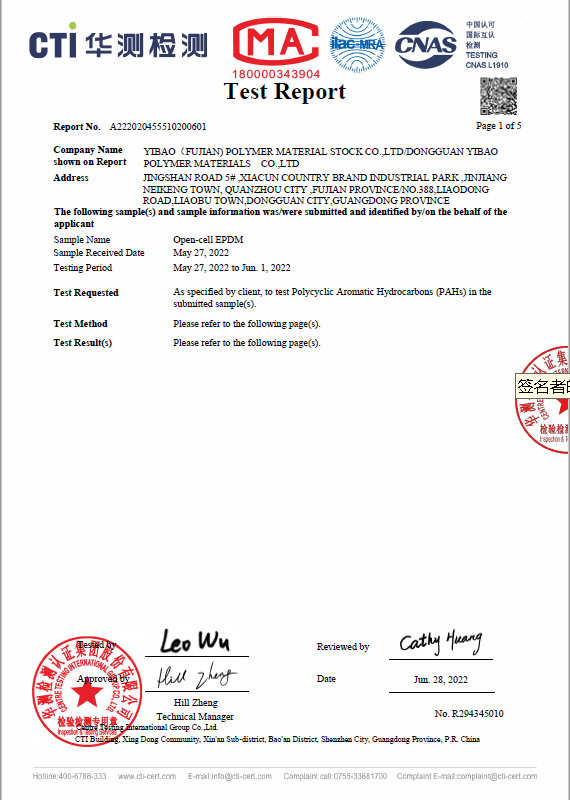

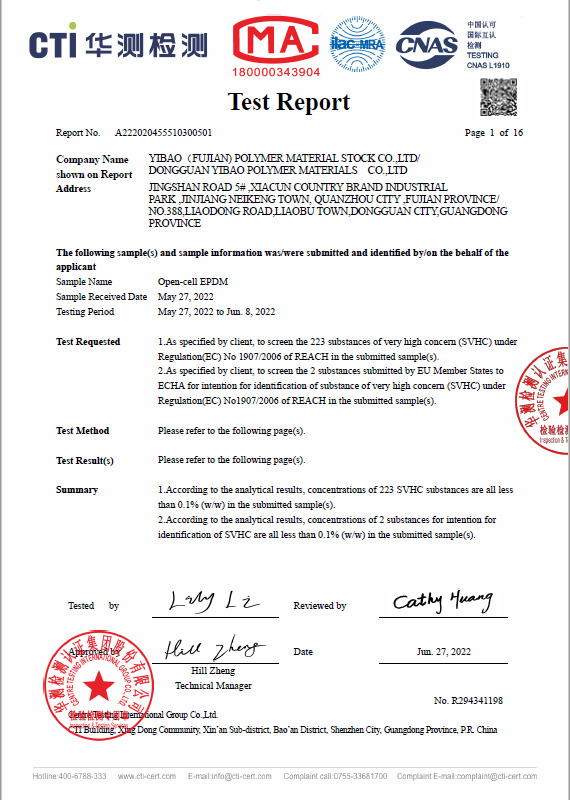

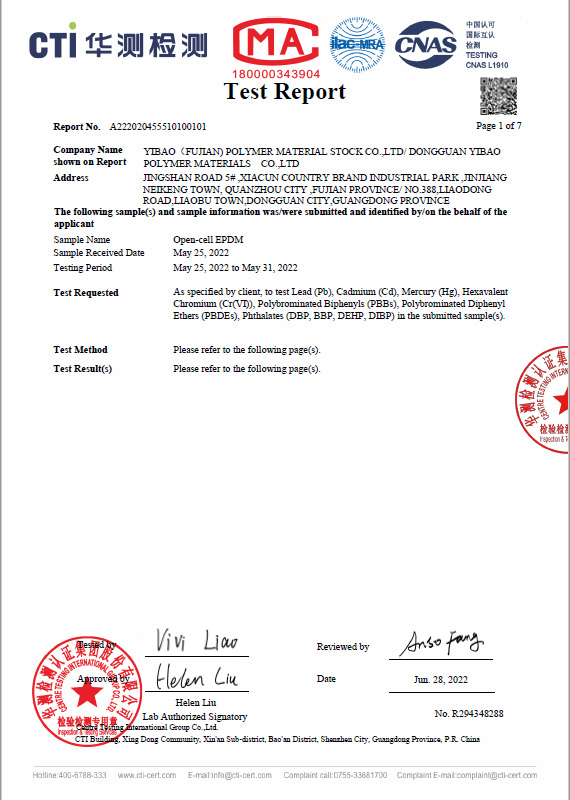

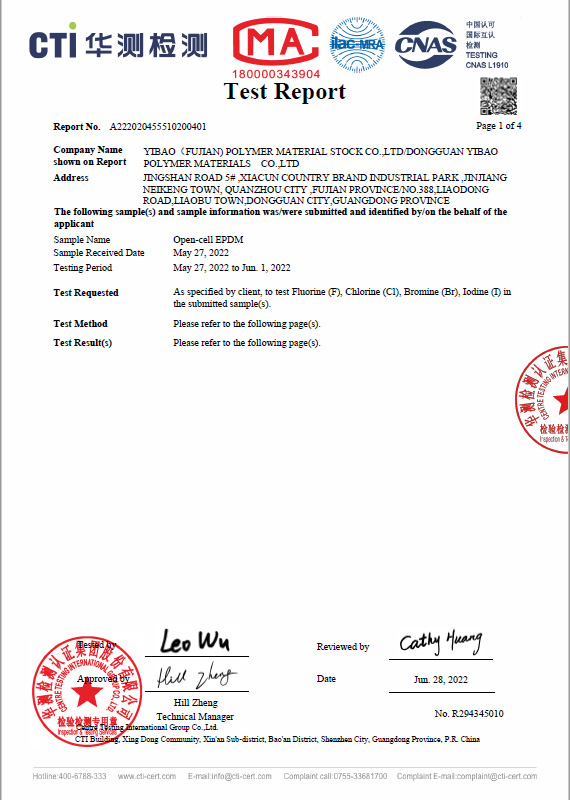

Open Cell EPDM Foam Sponge CTI Test Report:

CTI PAHs Test Report

CTI REACH Test Report

CTI RoHS Test Report

CTI Halogen-Free Test Report

Explain: Please contact sales representative for the complete test report.

Open Cell EPDM Foam Sponge Can Fulfill The Below International Standards:

| PAHs | 15 substances (PAHs) for REACH Annex XVII Article 50 Amendment (Regulation (EC) No 1272/2013) |

| REACH (SVHC) | 224 + 1 Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 of REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| Halogen-Free | Restriction of halogen content - fluorine (F), chlorine (Cl), bromine (Br) and iodine (I) - EN 14582:2016 |