Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

EVA Foam Sponge - Manufacturer

EVA is a closed-cell sponge made of ethylene-vinyl acetate. Acid resistance, alkali resistance, chemical resistance, durable, non-absorbent, light weight, good formability, easy to process and so on. Suitable for footwear, sports and leisure products, toys, floor/yoga mats, packaging, medical equipment, protective gear, water sports products, etc.

The price of EVA foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

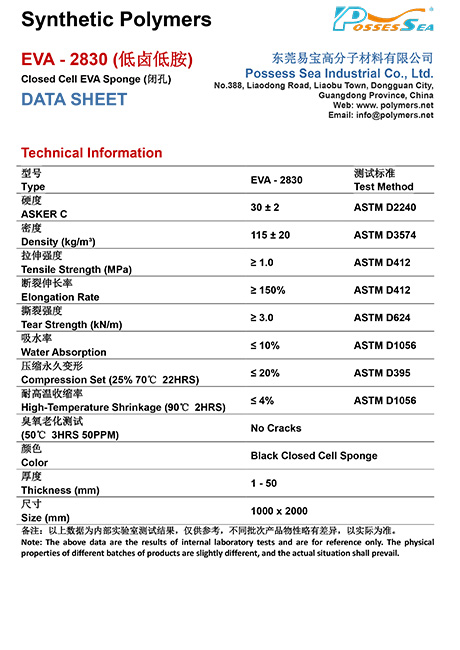

EVA Foam Sponge - EVA-2830

Explain: EVA-2830 is a closed cell EVA foam sponge with halogen-free and low amine.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 30 ± 2.

Density (kg/m³): 115 ± 20.

Tensile Strength (MPa): ≥ 1.0.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 10%.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Colors and specifications can be developed and customized according to customer requirements.

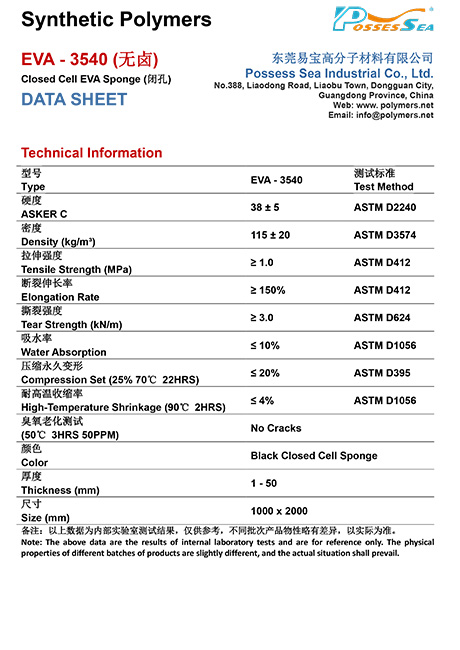

EVA Foam Sponge - EVA-3540

Explain: EVA-3540 is a halogen-free closed cell EVA foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 38 ± 5.

Density (kg/m³): 115 ± 20.

Tensile Strength (MPa): ≥ 1.0.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 10%.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Colors and specifications can be developed and customized according to customer requirements.

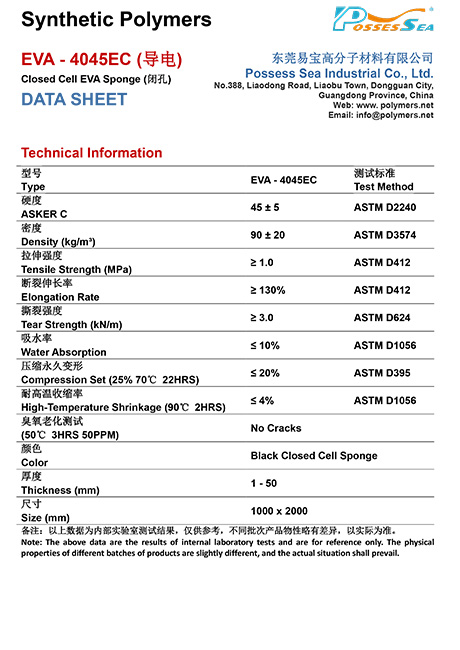

EVA Foam Sponge - EVA-4045EC

Explain: EVA-4045EC is a conductive closed cell EVA foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 45 ± 5.

Density (kg/m³): 90 ± 20.

Tensile Strength (MPa): ≥ 1.0.

Elongation Rate: ≥ 130%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 10%.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Colors and specifications can be developed and customized according to customer requirements.

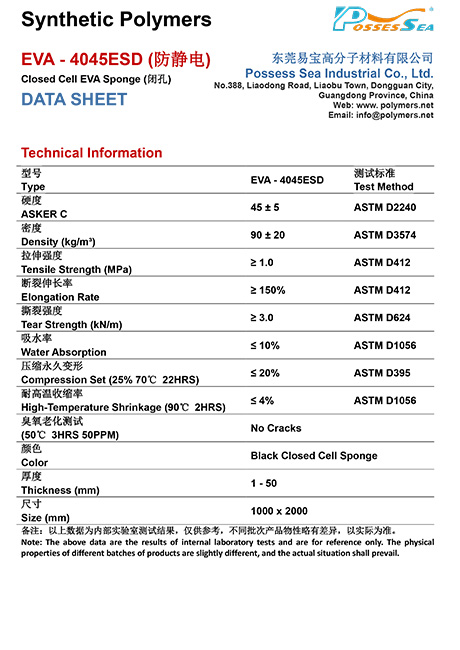

EVA Foam Sponge - EVA-4045ESD

Explain: EVA-4045ESD is an anti-static closed cell EVA foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 45 ± 5.

Density (kg/m³): 90 ± 20.

Tensile Strength (MPa): ≥ 1.0.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 10%.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Colors and specifications can be developed and customized according to customer requirements.

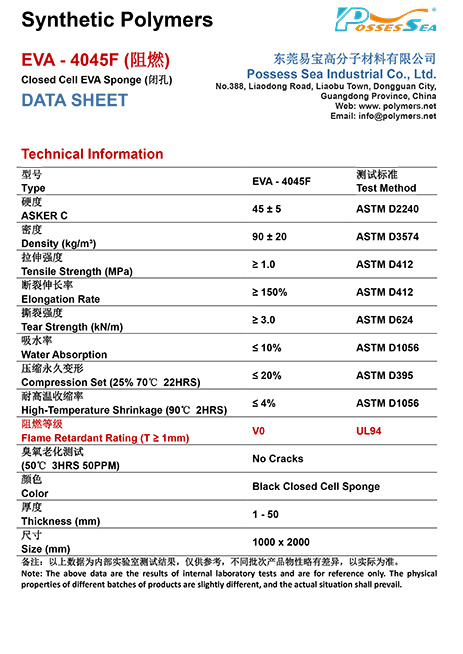

EVA Foam Sponge - EVA-4045F

Explain: EVA-4045F is a flame retardant closed cell EVA foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 45 ± 5.

Density (kg/m³): 90 ± 20.

Tensile Strength (MPa): ≥ 1.0.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 10%.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Flame Retardant Rating (UL 94): ≥1mm V0.

Note: Colors and specifications can be developed and customized according to customer requirements.

List of Physical Properties of EVA Foam Spon:

| Type | Hardness | Density | Tensile Strength | Flame Retardant Rating | Size | Note: |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

UL94 | mm | / | |

| EVA-2830 | 30 ± 2 | 115 ± 20 | ≥ 1.0 | / | 1000 x 2000 | Halogen-Free and Low Amine |

| EVA-3540 | 38 ± 5 | 115 ± 20 | ≥ 1.0 | / | 1000 x 2000 | Halogen-Free |

| EVA-4045EC | 45 ± 5 | 90 ± 20 | ≥ 1.0 | / | 1000 x 2000 | Conductive |

| EVA-4045ESD | 45 ± 5 | 90 ± 20 | ≥ 1.0 | / | 1000 x 2000 | Anti-Static |

| EVA-4045F | 45 ± 5 | 90 ± 20 | ≥ 1.0 | V0 | 1000 x 2000 | Flame Retardant |