Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

EPDM Foam Sponge - Manufacturer

EPDM is a copolymer of ethylene, propylene and a small amount of non-conjugated diene. It has excellent weather resistance, ozone resistance, chemical resistance, heat resistance and insulation. It is usually used in outdoor and harsh environments.

We produce open-cell and closed-cell EPDM. Blending products of EPDM and CR or SBR are also common types. Such materials are mainly used in the automotive industry, electronic industry, rail transit, construction industry, etc. that require sealing , shock absorption, flame retardant scene.

We provide block of EPDM foam sponges with various specifications and different properties, and can be customized according to customer requirements. In addition, we can also provide customers with roughing (slicing / cutting) services. Our company has also long-term cooperate with various downstream factory to finishing (die cutting / forming) services.

EPDM foam sponge is a highly competitive product of our company. At present, it has cooperated with a number of downstream die-cutting/molding factorys and has been shipped to various traditional car companies and new energy car companies in large quantities. It has also achieved excellent results in the application of electronic/electrical buffer materials. In addition, in terms of rail transit, shipbuilding, aerospace applications, it also cooperates with related enterprises to steadily promote trial, and small batch production is in progress.

Open Cell EPDM Foam Sponge

Explain: Our open cell EPDM foam sponge is a versatile high performance sealing material. It offers many of the same properties as closed cell materials, including durability and resistance to weathering, UV light, aging and ozone. The open-cell structure gives it excellent recovery properties or resistance to Compression Set, capable of returning to its original shape after compression. When the pressure is released, the air pockets in its porous tissue return to their original shape, making them ideal for applications that require sealing or cushioning of irregular depths or uneven areas.

Note: The more information and introduction, please refer to the relevant webpage:➜ Open Cell EPDM Foam Sponge.

Closed Cell EPDM Foam Sponge

Explain: Our closed cell EPDM form sponge is a high quality closed cell material that is easy to form an airtight and waterproof seal. Excellent UV and ozone resistance, ideal for outdoor sealing applications. In addition to providing excellent weather resistance, closed cell EPDM also provides good flexibility, Tensile Strength and recovery properties. The closed-cell construction provides excellent heat sealing, prevents the build-up of bacteria and mold, and handles high-pressure sealing applications at better speeds, making them more durable, which in turn increases the material's life expectancy in demanding applications.

Note: The more information and introduction, please refer to the relevant webpage:➜ Closed Cell EPDM Foam Sponge.

EPDM & EVA Blend Foam Sponge

Explain: EPDM is a thermosetting elastomer rubber, while EVA is a thermoplastic. Their blend products have the softness and flexibility of CR (Neoprene) rubber, high durability and weather resistance, and the halogen content of the body is very low, so It has excellent flame retardant properties and to replace CR (Neoprene) rubber in specific applications.

Note: The more information and introduction, please refer to the relevant webpage:➜ EPDM + EVA Blend Foam Sponge.

EPDM & CR & SBR Blend Foam Sponge

Explain: Different polymers are available for different requirements and applications, including ethylene-propylene-diene rubber (EPDM), neoprene (CR), and styrene-butadiene rubber (SBR). The closed-cell structure has the characteristics of high mechanical strength, good elasticity, low thermal conductivity, good heat preservation, waterproof and flame retardant. By blending the three, different properties can be obtained and cost-effectiveness can be improved (SBR sponge is cheap).

Note: The more information and introduction, please refer to the relevant webpage:➜ EPDM + CR + SBR Blend Foam Sponge.

List of Physical Properties of Open Cell EPDM Foam Sponge:

| Type | Density | Tensile Strength | Tear Strength | 25% Compression Deformation | Size |

| ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D624 (kN/m) |

ASTM D1056 (kPa) |

mm | |

| EP-8011C | 90 ± 20 | ≥ 0.07 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-70 | 75 ± 15 | ≥ 0.05 | ≥ 0.35 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-70V | 70 ± 15 | ≥ 0.05 | ≥ 0.35 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-90 | 90 ± 30 | ≥ 0.05 | ≥ 0.5 | 1 - 5 | 1000 x 2000 |

| EP-8011C-90A | 75 ± 15 | ≥ 0.05 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-90B | 110 ± 30 | ≥ 0.08 | ≥ 0.6 | 6 - 15 | 1000 x 2000 |

| EP-8011C-90ST | 100 ± 20 | ≥ 0.05 | ≥ 0.5 | 1 - 7 | 1000 x 2000 |

| EP-8011C-90W | 90 ± 30 | ≥ 0.05 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-110V | 110 ± 20 | ≥ 0.06 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8011C-120ST | 120 ± 20 | ≥ 0.06 | ≥ 0.5 | 1 - 7 | 1000 x 2000 |

| EP-8011C-130V | 130 ± 20 | ≥ 0.07 | ≥ 0.5 | 1.5 - 7 | 1000 x 2000 |

| EP-8012 | 120 ± 30 | ≥ 0.06 | ≥ 0.5 | 2 - 5 | 1000 x 2000 |

| EP-8013 | 150 ± 30 | ≥ 0.06 | ≥ 0.5 | 2 - 5 | 1000 x 2000 |

| EP-8015 | 200 ± 30 | ≥ 0.1 | ≥ 0.6 | 2 - 5 | 1000 x 2000 |

| EP-8016 | 100 ± 20 | ≥ 0.08 | ≥ 0.5 | 1 - 3.5 | 1000 x 2000 |

| EP-8017 | 120 ± 20 | ≥ 0.1 | ≥ 0.6 | 1 - 3.5 | 1000 x 2000 |

Note: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

List of Physical Properties of Closed Cell EPDM Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| EP-6005 | 8 ± 3 | 100 ± 30 | ≥ 0.3 | 20 - 50 | / | 1000 x 2000 1000 x 4000 |

| EP-6008 | 10 ± 5 | 75 ± 15 | ≥ 0.3 | 15 - 35 | / | 1000 x 2000 |

| EP-6008A | 8 ± 5 | 75 ± 15 | ≥ 0.2 | 15 - 45 | / | 1000 x 2000 |

| EP-6010 | 10 ± 3 | 130 ± 20 | ≥ 0.35 | 25 - 45 | / | 1000 x 2000 |

| EP-6015 | 15 ± 3 | 130 ± 30 | ≥ 0.4 | 25 - 55 | / | 1000 x 2000 1000 x 4000 |

| EP-6015G | 15 ± 3 | 130 ± 30 | ≥ 0.4 | 25 - 55 | / | 1000 x 2000 |

| EP-6018 | 18 ± 3 | 140 ± 30 | ≥ 0.5 | 30 - 60 | / | 1000 x 2000 1000 x 4000 |

| EP-6018T | 18 ± 3 | 200 ± 30 | ≥ 0.5 | 35 - 65 | / | 1000 x 2000 |

| EP-6020 | 18 ± 3 | 140 ± 30 | ≥ 0.3 | 35 - 65 | HBF | 1000 x 2000 |

| EP-6022 | 20 ± 3 | 140 ± 30 | ≥ 0.5 | 35 - 65 | / | 1000 x 2000 1000 x 4000 |

| EP-6022W | 20 ± 5 | 140 ± 30 | ≥ 0.4 | 35 - 65 | / | 1000 x 2300 |

| EP-6022V | 15 ± 5 | 130 ± 30 | ≥ 0.35 | 30 - 60 | HBF | 1000 x 2000 1000 x 4000 |

| EP-6022CV | 20 ± 3 | 175 ± 25 | ≥ 0.4 | 35 - 65 | HBF | 1000 x 2000 1000 x 4000 |

| EP-6022F1 | 20 ± 5 | 160 ± 30 | ≥ 0.4 | 30 - 80 | HF1 | 1000 x 2000 1000 x 4000 |

| EP-6025 | 20 ± 5 | 160 ± 30 | ≥ 0.5 | 40 - 90 | / | 1000 x 2000 |

| EP-6025P | 25 ± 5 | 200 ± 40 | ≥ 0.6 | 40 - 90 | / | 1000 x 2000 |

| EP-6030 | 30 ± 5 | 200 ± 30 | ≥ 0.8 | 50 - 100 | / | 1000 x 2000 |

| EP-6040 | 40 ± 5 | 270 ± 50 | ≥ 1.0 | 90 - 150 | / | 1000 x 2000 |

Explain: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

List of Physical Properties of EPDM & EVA Blend Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| EE-1525F | 15 ± 5 | 200 ± 30 | ≥ 0.5 | 30 - 80 | V0 | 1000 x 2000 |

| EE-2535F | 25 ± 5 | 220 ± 30 | ≥ 0.6 | 40 - 100 | V0 | 1000 x 2000 |

| EE-3545F | 35 ± 5 | 270 ± 30 | ≥ 0.7 | 70 - 140 | V0 | 1000 x 2000 |

| EE-4555F | 45 ± 5 | 320 ± 30 | ≥ 0.8 | 100 - 200 | V0 | 1000 x 2000 |

Explain: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

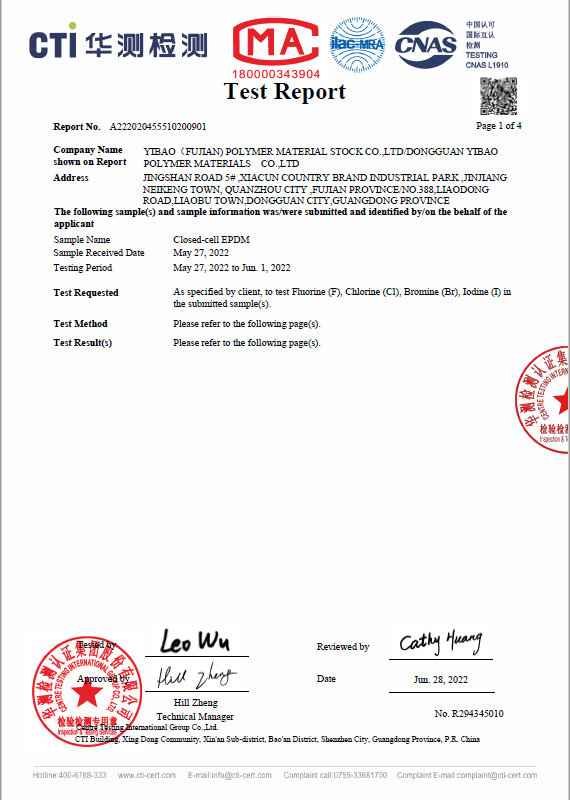

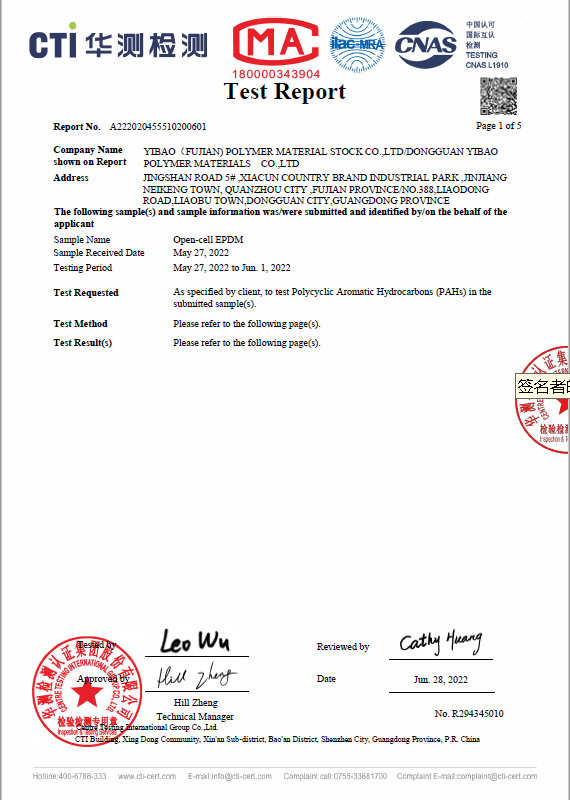

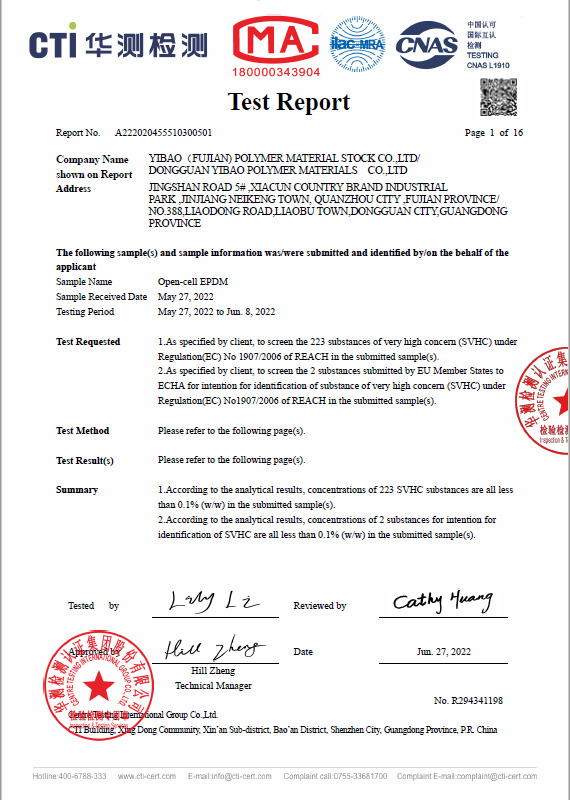

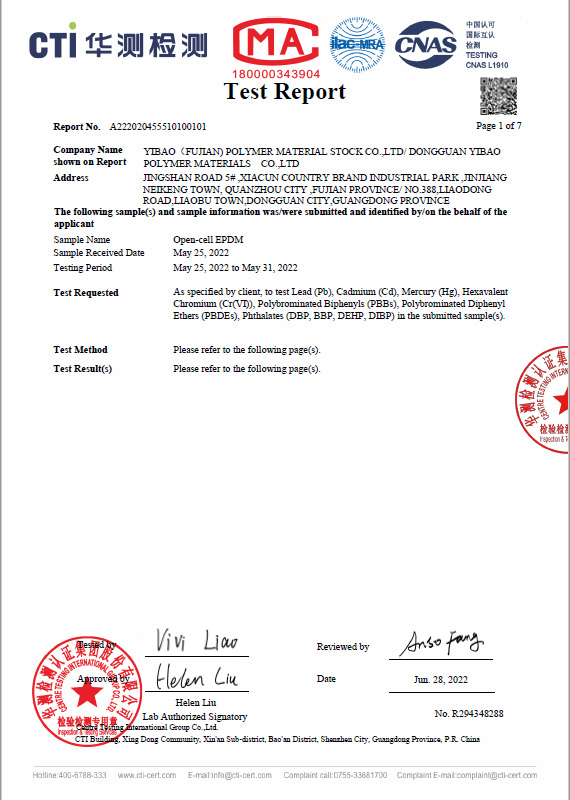

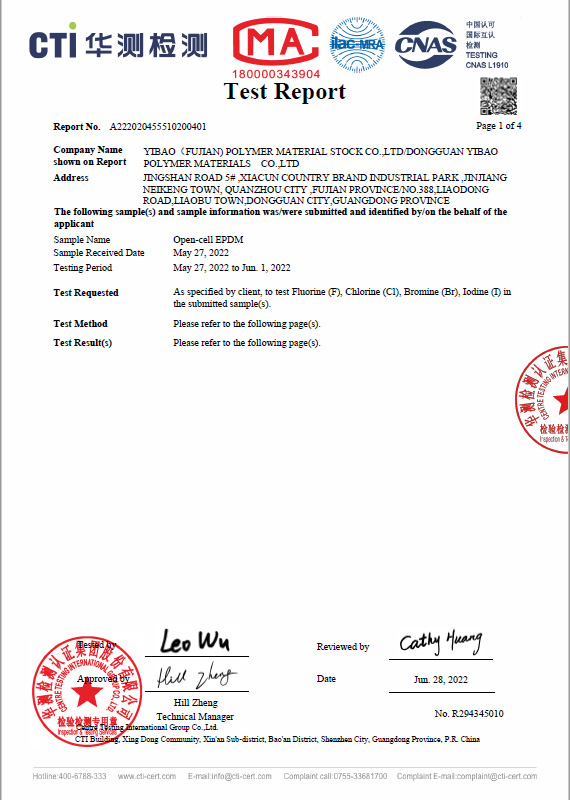

Open Cell EPDM Foam Sponge CTI Test Report:

CTI PAHs Test Report

CTI REACH Test Report

CTI RoHS Test Report

CTI Halogen-Free Test Report

Explain: Please contact sales representative for the complete test report.

Closed Cell EPDM Foam Sponge CTI Test Report:

CTI PAHs Test Report

CTI REACH Test Report

CTI RoHS Test Report

CTI Sulfur-Free Test Report