Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

CR (Neprene) Foam Sponge - Manufacturer

CR neoprene is a sponge with a closed cell structure. It has the characteristics of high mechanical strength, good elasticity, low thermal conductivity, good thermal insulation, waterproof, and flame retardant. It is suitable for gasket materials, thermal insulation materials, special Electronic components, anti-vibration materials, industrial equipment buffers, motor vehicles, ships (gaskets, seals and buffer materials).

The price of CR (Neprene) foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

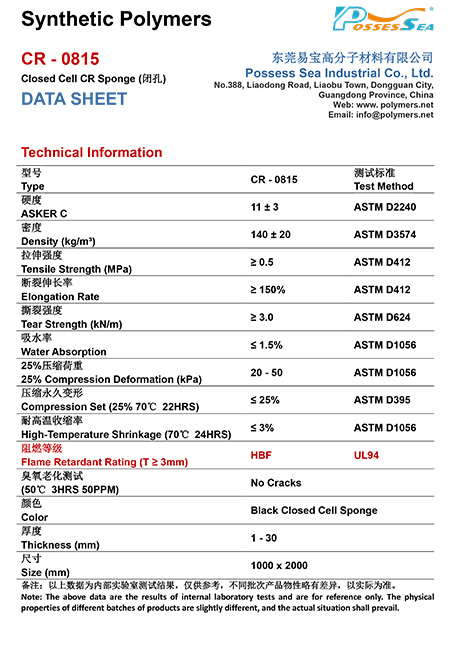

CR (Neoprene) Foam Sponge - CR-0815

Explain: CR-0815 is closed cell CR (Neoprene) foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 11 ± 3.

Density (kg/m³): 140 ± 20.

Tensile Strength (MPa): ≥ 0.5.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 1.5%.

25% Compression Deformation (kPa): 20 - 50.

Compression Set (25% 70℃ 22HRS): ≤ 25%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 3%.

Flame Retardant Rating (UL 94): ≥3mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

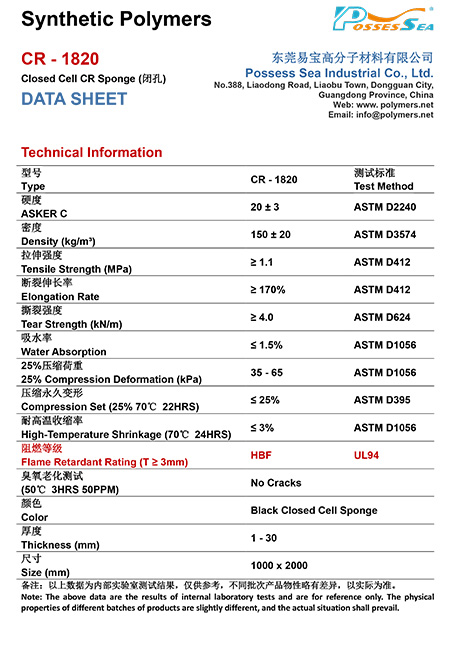

CR (Neoprene) Foam Sponge - CR-1820

Explain: CR-1820 is closed cell CR (Neoprene) foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 20 ± 3.

Density (kg/m³): 150 ± 20.

Tensile Strength (MPa): ≥ 1.1.

Elongation Rate: ≥ 170%.

Tear Strength (kN/m): ≥ 4.0.

Water Absorption: ≤ 1.5%.

25% Compression Deformation (kPa): 35 - 65.

Compression Set (25% 70℃ 22HRS): ≤ 25%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 3%.

Flame Retardant Rating (UL 94): ≥3mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

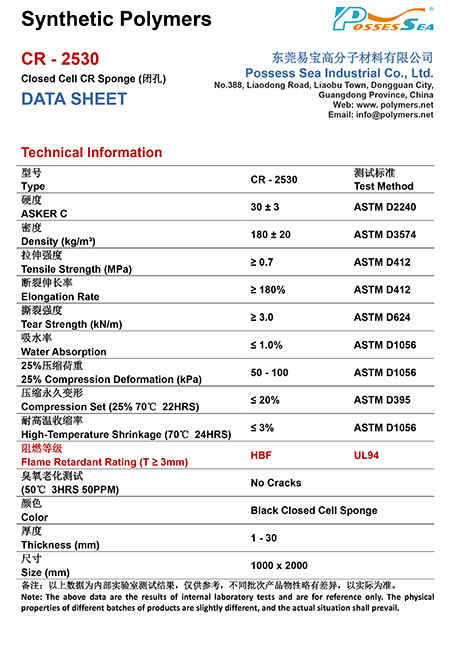

CR (Neoprene) Foam Sponge - CR-2530

Explain: CR-2530 is closed cell CR (Neoprene) foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 30 ± 3.

Density (kg/m³): 180 ± 20.

Tensile Strength (MPa): ≥ 0.7.

Elongation Rate: ≥ 180%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 1.0%.

25% Compression Deformation (kPa): 50 - 100.

Compression Set (25% 70℃ 22HRS): ≤ 20%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 3%.

Flame Retardant Rating (UL 94): ≥3mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

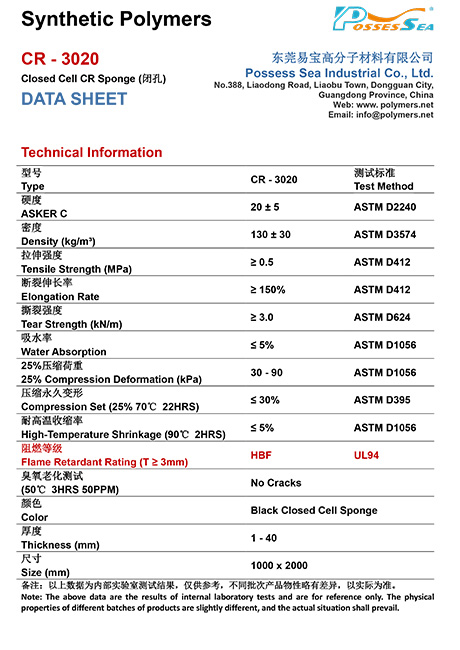

CR (Neoprene) Foam Sponge - CR-3020

Explain: CR-3020 is closed cell CR (Neoprene) foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 20 ± 5.

Density (kg/m³): 130 ± 30.

Tensile Strength (MPa): ≥ 0.5.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 5.0%.

25% Compression Deformation (kPa): 30 - 90.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 5%.

Flame Retardant Rating (UL 94): ≥3mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

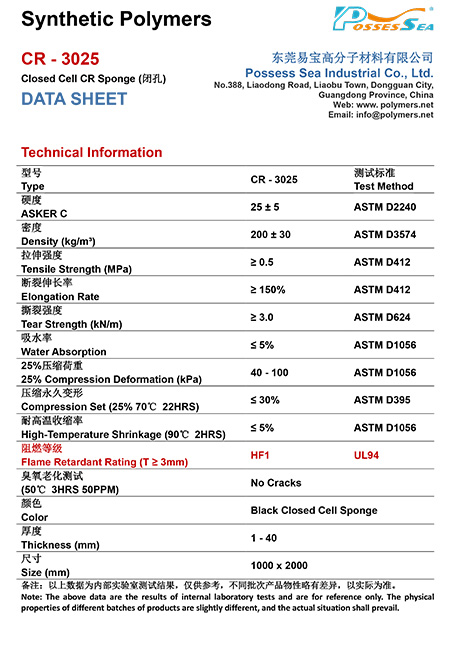

CR (Neoprene) Foam Sponge - CR-3025

Explain: CR-3025 is closed cell CR (Neoprene) foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 25 ± 5.

Density (kg/m³): 200 ± 30.

Tensile Strength (MPa): ≥ 0.5.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 5.0%.

25% Compression Deformation (kPa): 40 - 100.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 5%.

Flame Retardant Rating (UL 94): ≥3mm HB1.

Note: Similar to INOAC C-4305, colors and specifications can be developed and customized according to customer requirements.

List of Physical Properties of CR (Neoprene) Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| CR-0815 | 11 ± 3 | 140 ± 20 | ≥ 0.5 | 20 - 50 | HBF | 1000 x 2000 |

| CR-1820 | 20 ± 3 | 150 ± 20 | ≥ 1.1 | 30 - 65 | HBF | 1000 x 2000 |

| CR-2530 | 30 ± 3 | 180 ± 20 | ≥ 0.7 | 50 - 100 | HBF | 1000 x 2000 |

| CR-3020 | 20 ± 5 | 130 ± 30 | ≥ 0.5 | 30 - 90 | HBF | 1000 x 2000 |

| CR-3025 | 25 ± 5 | 200 ± 30 | ≥ 0.5 | 40 - 100 | HB1 | 1000 x 2000 |