Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

EPDM & EVA Blend Foam Sponge - Manufacturer

EPDM is a thermosetting elastomer rubber, while EVA is a thermoplastic. Their blend products have the softness and flexibility of CR (Neoprene) rubber, high durability and weather resistance, and the halogen content of the body is very low, so It has excellent flame retardant properties and to replace CR (Neoprene) rubber in specific applications.

Chlorine (Cl) is a halogen element, so neoprene (CR) and polyvinyl chloride (PVC) are both halogen-containing compounds, so it is impossible for these two substances or mixtures containing these two substances to be halogen-free. EPDM & EVA blend products are often called halogen-free flame retardant CR (Neoprene) rubber, but in fact this blend product has nothing to do with CR (Neoprene) rubber and does not contain CR (Neoprene) components.

The price of EPDM & EVA blend foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

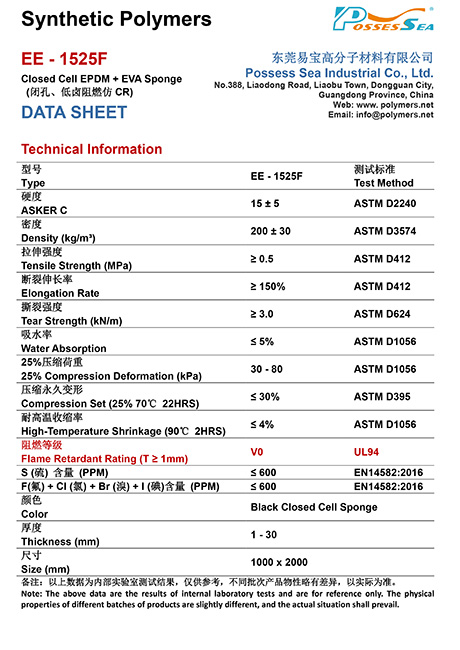

EPDM & EVA Blend Foam Sponge - EE-1525F

Explain: EE-1525F is a halogen-free and flame retardant closed cell EPDM & EVA blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 15 ± 5.

Density (kg/m³): 200 ± 30.

Tensile Strength (MPa): ≥ 0.5.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 30 - 80.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

Flame Retardant Rating (UL 94): ≥1mm V0.

Sulfur (S) Content (PPM): ≤ 600.

Fluorine (F) + Chlorine (Cl) + Bromine (Br) + Iodine (I) Content (PPM): ≤ 600.

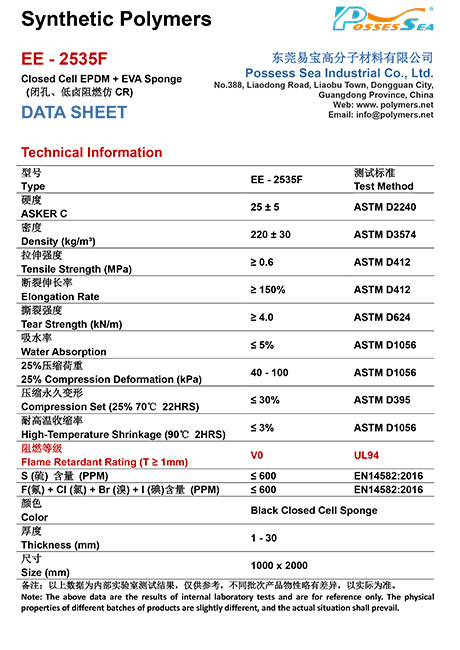

EPDM & EVA Blend Foam Sponge - EE-2535F

Explain: EE-2535F is a halogen-free and flame retardant closed cell EPDM & EVA blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 25 ± 5.

Density (kg/m³): 220 ± 30.

Tensile Strength (MPa): ≥ 0.6.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 4.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 40 - 100.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

Flame Retardant Rating (UL 94): ≥1mm V0.

Sulfur (S) Content (PPM): ≤ 600.

Fluorine (F) + Chlorine (Cl) + Bromine (Br) + Iodine (I) Content (PPM): ≤ 600.

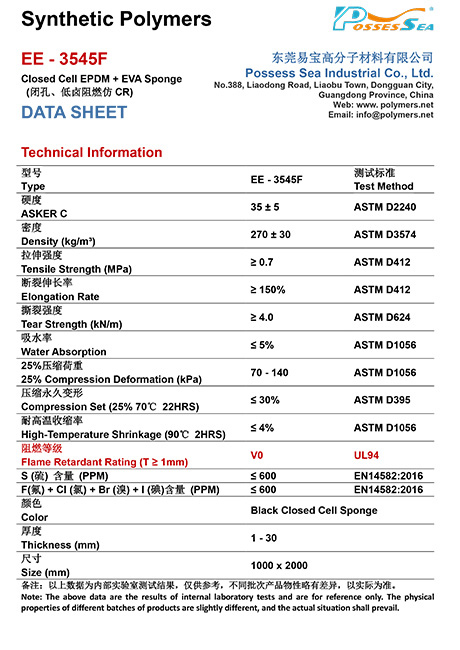

EPDM & EVA Blend Foam Sponge - EE-3545F

Explain: EE-3545F is a halogen-free and flame retardant closed cell EPDM & EVA blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 35 ± 5.

Density (kg/m³): 270 ± 30.

Tensile Strength (MPa): ≥ 0.7.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 4.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 70 - 140.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

Flame Retardant Rating (UL 94): ≥1mm V0.

Sulfur (S) Content (PPM): ≤ 600.

Fluorine (F) + Chlorine (Cl) + Bromine (Br) + Iodine (I) Content (PPM): ≤ 600.

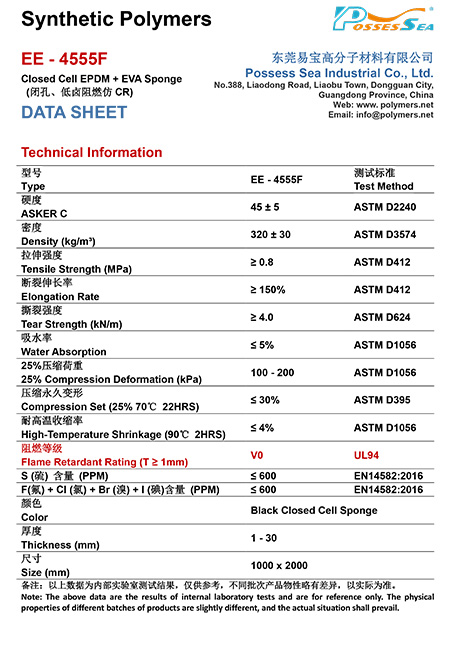

EPDM & EVA Blend Foam Sponge - EE-4555F

Explain: EE-4555F is a halogen-free and flame retardant closed cell EPDM & EVA blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 45 ± 5.

Density (kg/m³): 320 ± 30.

Tensile Strength (MPa): ≥ 0.8.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 4.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 100 - 2000.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

Flame Retardant Rating (UL 94): ≥1mm V0.

Sulfur (S) Content (PPM): ≤ 600.

Fluorine (F) + Chlorine (Cl) + Bromine (Br) + Iodine (I) Content (PPM): ≤ 600.

List of Physical Properties of EPDM & EVA Blend Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| EE-1525F | 15 ± 5 | 200 ± 30 | ≥ 0.5 | 30 - 80 | V0 | 1000 x 2000 |

| EE-2535F | 25 ± 5 | 220 ± 30 | ≥ 0.6 | 40 - 100 | V0 | 1000 x 2000 |

| EE-3545F | 35 ± 5 | 270 ± 30 | ≥ 0.7 | 70 - 140 | V0 | 1000 x 2000 |

| EE-4555F | 45 ± 5 | 320 ± 30 | ≥ 0.8 | 100 - 200 | V0 | 1000 x 2000 |

Explain: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

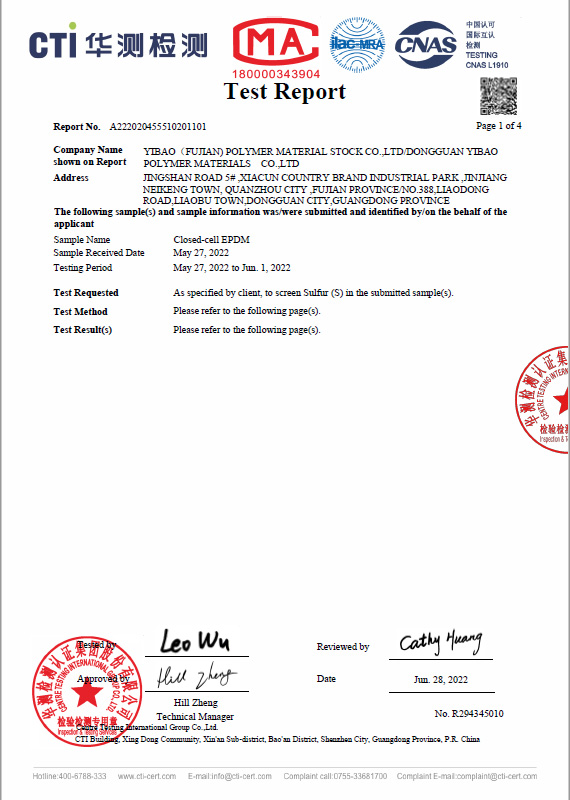

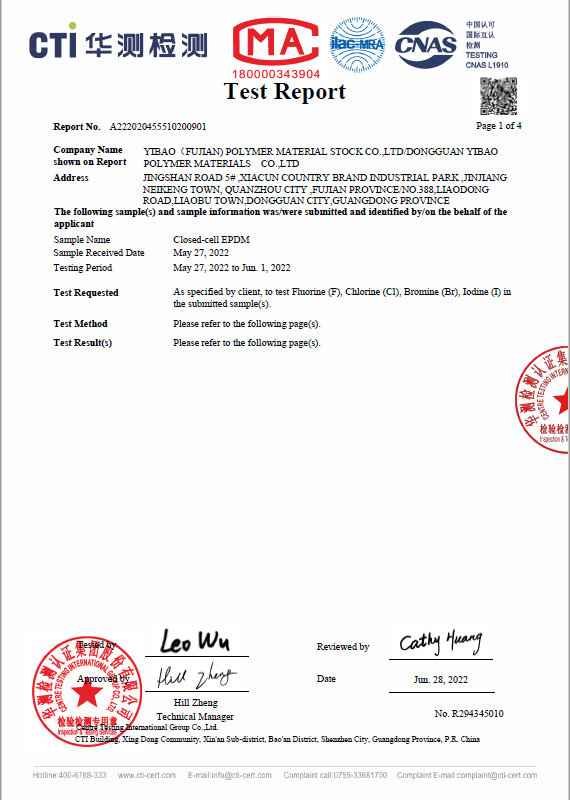

EPDM & EVA Blend Foam Sponge CTI Test Report:

CTI Sulfur-Free Test Report

CTI Halogen-Free Test Report

Explain: Please contact sales representative for the complete test report.

EPDM & EVA Blend Foam Sponge Can Fulfill The Below International Standards:

| PAHs | 15 substances (PAHs) for REACH Annex XVII Article 50 Amendment (Regulation (EC) No 1272/2013) |

| REACH (SVHC) | 224 + 1 Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 of REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| Sulfur-Free | Restriction of sulfur content - sulfur (S) - EN 14582:2016 |

| Halogen-Free | Restriction of halogen content - fluorine (F), chlorine (Cl), bromine (Br) and iodine (I) - EN 14582:2016 |