Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

EPDM & CR & SBR Blend Foam Sponge - Manufacturer

Different polymers are available for different requirements and applications, including ethylene-propylene-diene rubber (EPDM), neoprene (CR), and styrene-butadiene rubber (SBR). The closed-cell structure has the characteristics of high mechanical strength, good elasticity, low thermal conductivity, good heat preservation, waterproof and flame retardant. By blending the three, different properties can be obtained and cost-effectiveness can be improved (SBR sponge is cheap).

The price of EPDM & CR & SBR blend foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

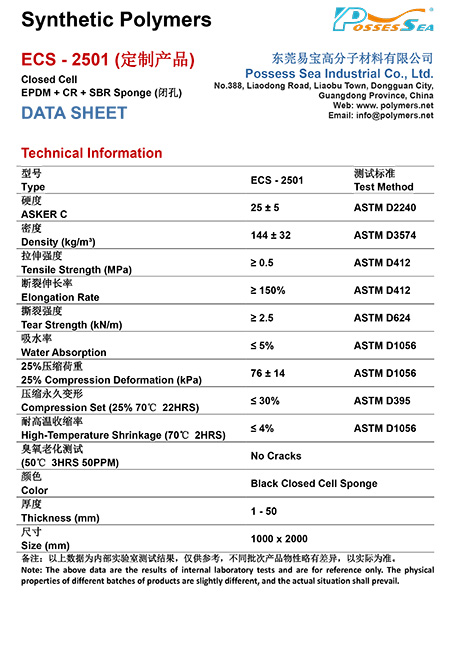

EPDM & CR & SBR Blend Foam Sponge - ECS-2501

Explain: ECS-2501 is a customized closed cell EPDM & CR & SBR blend foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 25 ± 5.

Density (kg/m³): 144 ± 32.

Tensile Strength (MPa): ≥ 0.5.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 2.5.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 76 ± 14.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Note: Colors and specifications can be developed and customized according to customer requirements.

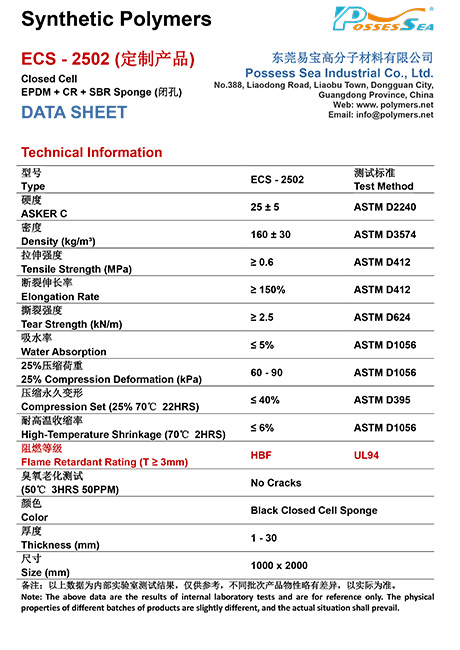

EPDM & CR & SBR Blend Foam Sponge - ECS-2502

Explain: ECS-2502 is a customized closed cell EPDM & CR & SBR blend foam sponge.

Color: Black.

Size (mm): 1000 X 2000.

Hardness (ASKER C): 25 ± 5.

Density (kg/m³): 160 ± 30.

Tensile Strength (MPa): ≥ 0.6.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 2.5.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 60 - 90.

Compression Set (25% 70℃ 22HRS): ≤ 40%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 8%.

Flame Retardant Rating (UL 94): ≥3mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

List of Physical Properties of EPDM & CR & SBR Blend Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| ECS-2501 | 25 ± 5 | 144 ± 32 | ≥ 0.5 | 76 ± 14 | / | 1000 x 2000 |

| ECS-2502 | 25 ± 5 | 160 ± 30 | ≥ 0.6 | 60 - 90 | HBF | 1000 x 2000 |