Possess Sea Industrial Co., Ltd. - Synthetic Polymers

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Professional Polymer Foam Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

NBR & PVC Blend Foam Sponge - Manufacturer

The blend of nitrile rubber (NBR) and polyvinyl chloride (PVC) maintains the respective characteristics of NBR and PVC. In addition, PVC improves the ozone resistance and abrasion resistance of NBR, and NBR improves the flexibility of PVC. The blend products have better physical properties than monomers, and are used to replace NBR, PVC and CR (Neoprene) products.

Because NBR & PVC blend products have similar physical properties to CR (Neoprene) and are cheaper than CR (Neoprene), they are used to replace CR (Neoprene) in many occasions, often referred to as imitation CR or industrial CR, but it must be pointed out that it is not CR (Neoprene) and does not contain CR (Neoprene).

The price of NBR & PVC blend foam sponge is calculated by volume. We usually list the price in cubic meters. For rough processed sheet products, the volume is calculated by multiplying the length, width and height, and then calculate the single price of the sheet by the price in cubic meters.

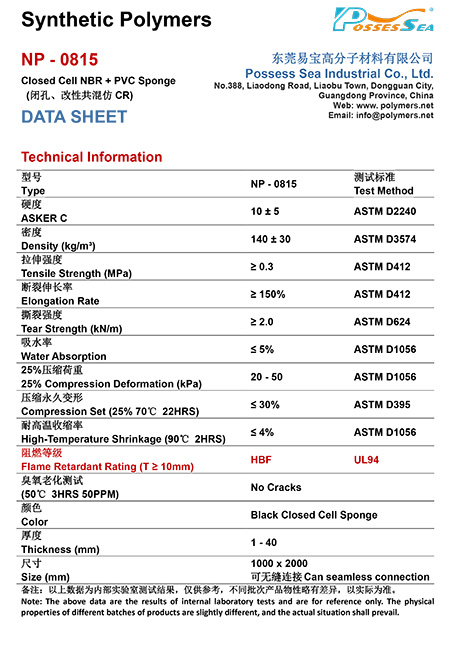

NBR & PVC Blend Foam Sponge - NP-0815

Explain: NP-0815 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000 (Can seamless connection).

Hardness (ASKER C): 10 ± 5.

Density (kg/m³): 140 ± 30.

Tensile Strength (MPa): ≥ 0.3.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 2.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 20 - 50.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Flame Retardant Rating (UL 94): ≥10mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

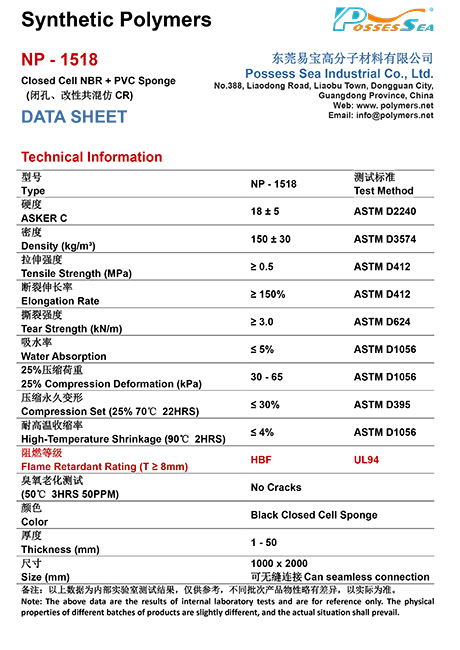

NBR & PVC Blend Foam Sponge - NP-1518

Explain: NP-1518 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000 (Can seamless connection).

Hardness (ASKER C): 18 ± 5.

Density (kg/m³): 150 ± 30.

Tensile Strength (MPa): ≥ 0.5.

Elongation Rate: ≥ 150%.

Tear Strength (kN/m): ≥ 3.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 30 - 65.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Flame Retardant Rating (UL 94): ≥8mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

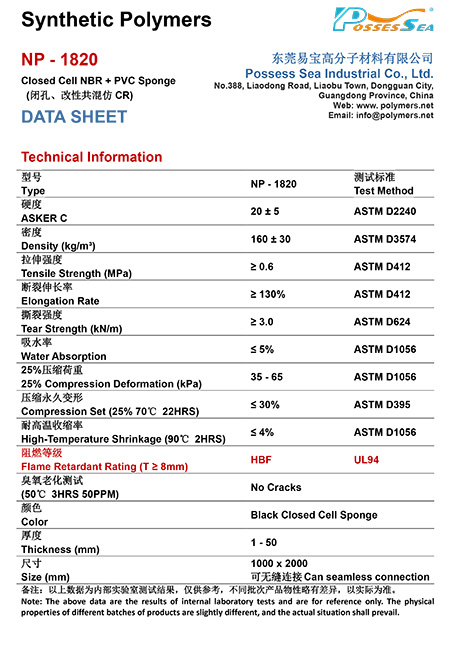

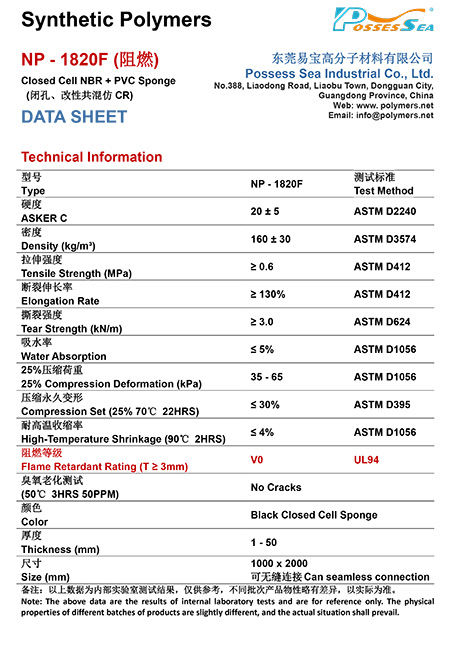

NBR & PVC Blend Foam Sponge - NP-1820

Explain: NP-1820 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

| Type | NP-1820 | NP-1820F |

| Color | Black | |

| Size (mm) | 1000 X 2000 (Can seamless connection) | |

| Hardness (ASKER C) | 20 ± 5 | |

| Density (kg/m³) | 160 ± 30 | |

| Tensile Strength (MPa) | ≥ 0.6 | |

| Elongation Rate | ≥ 130% | |

| Tear Strength (kN/m) | ≥ 3.0 | |

| Water Absorption | ≤ 5% | |

| 25% Compression Deformation (kPa) | 35 - 65 | |

| Compression Set (25% 70℃ 22HRS) |

≤ 30% | |

| High-Temperature Shrinkage (90℃ 2HRS) | ≤ 4% | |

| Flame Retardant Rating (UL 94) | ≥8mm HBF | ≥3mm V0 |

Note: Colors and specifications can be developed and customized according to customer requirements.

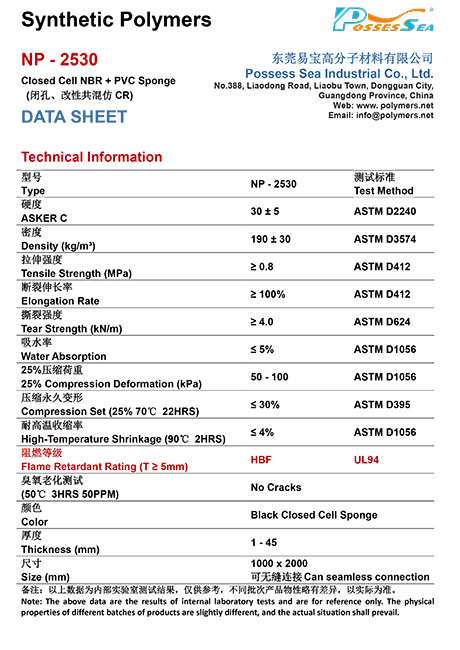

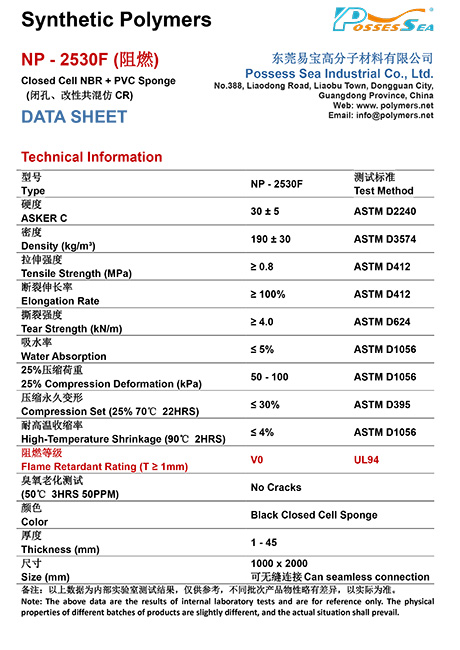

NBR & PVC Blend Foam Sponge - NP-2530

Explain: NP-2530 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

| Type | NP-2530 | NP-2530F |

| Color | Black | |

| Size (mm) | 1000 X 2000 (Can seamless connection) | |

| Hardness (ASKER C) | 30 ± 5 | |

| Density (kg/m³) | 190 ± 30 | |

| Tensile Strength (MPa) | ≥ 0.8 | |

| Elongation Rate | ≥ 100% | |

| Tear Strength (kN/m) | ≥ 4.0 | |

| Water Absorption | ≤ 5% | |

| 25% Compression Deformation (kPa) | 50 - 100 | |

| Compression Set (25% 70℃ 22HRS) |

≤ 30% | |

| High-Temperature Shrinkage (90℃ 2HRS) | ≤ 4% | |

| Flame Retardant Rating (UL 94) | ≥5mm HBF | ≥1mm V0 |

Note: Colors and specifications can be developed and customized according to customer requirements.

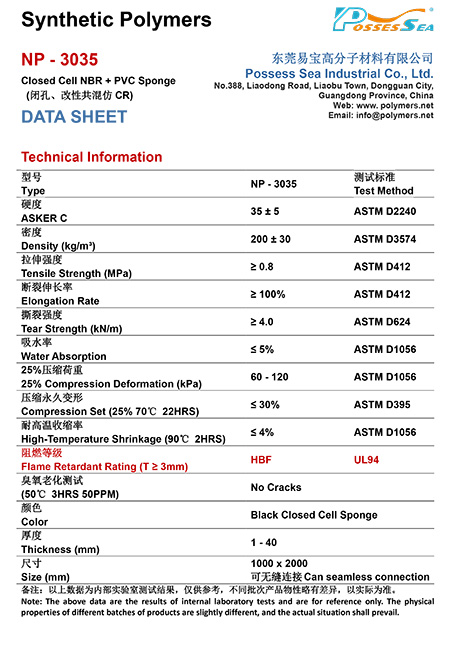

NBR & PVC Blend Foam Sponge - NP-3035

Explain: NP-3035 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000 (Can seamless connection).

Hardness (ASKER C): 35 ± 5.

Density (kg/m³): 200 ± 30.

Tensile Strength (MPa): ≥ 0.8.

Elongation Rate: ≥ 100%.

Tear Strength (kN/m): ≥ 4.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 60 - 120.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Flame Retardant Rating (UL 94): ≥3mm HBF.

Note: Colors and specifications can be developed and customized according to customer requirements.

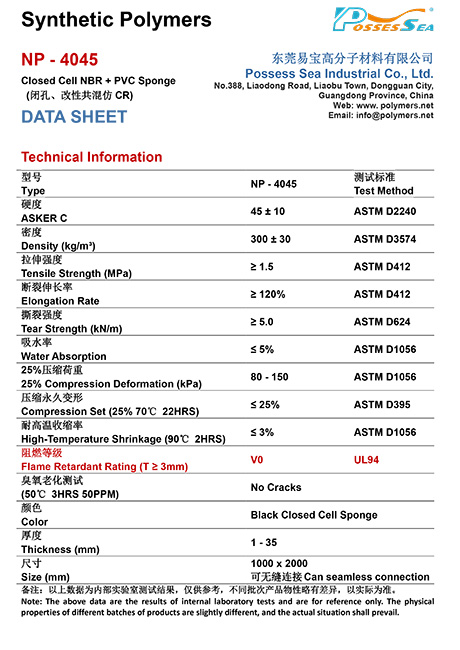

NBR & PVC Blend Foam Sponge - NP-4045

Explain: NP-4045 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000 (Can seamless connection).

Hardness (ASKER C): 45 ± 10.

Density (kg/m³): 300 ± 30.

Tensile Strength (MPa): ≥ 1.5.

Elongation Rate: ≥ 120%.

Tear Strength (kN/m): ≥ 5.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 80 - 150.

Compression Set (25% 70℃ 22HRS): ≤ 25%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 3%.

Flame Retardant Rating (UL 94): ≥3mm V0.

Note: Colors and specifications can be developed and customized according to customer requirements.

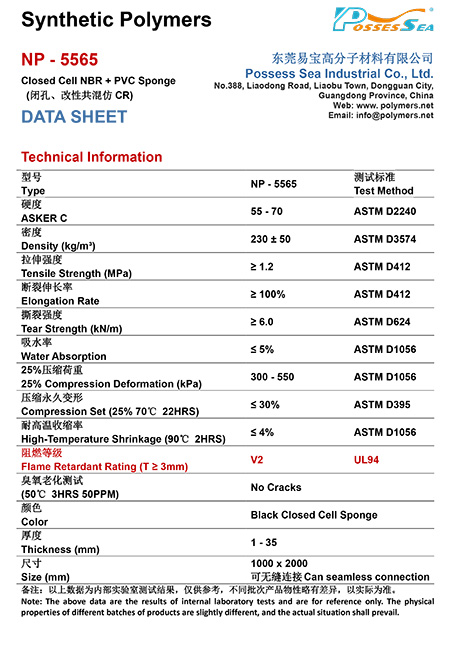

NBR & PVC Blend Foam Sponge - NP-5565

Explain: NP-5565 is a closed cell NBR & PVC blend foam sponge (Imitation CR foam sponge).

Color: Black.

Size (mm): 1000 X 2000 (Can seamless connection).

Hardness (ASKER C): 55 -70.

Density (kg/m³): 230 ± 50.

Tensile Strength (MPa): ≥ 1.2.

Elongation Rate: ≥ 100%.

Tear Strength (kN/m): ≥ 6.0.

Water Absorption: ≤ 5%.

25% Compression Deformation (kPa): 300 - 550.

Compression Set (25% 70℃ 22HRS): ≤ 30%.

High-Temperature Shrinkage (90℃ 2HRS): ≤ 4%.

Flame Retardant Rating (UL 94): ≥3mm V2.

Note: Colors and specifications can be developed and customized according to customer requirements.

List of Physical Properties of NBR & PVC Blend Foam Sponge:

| Type | Hardness | Density | Tensile Strength | 25% Compression Deformation | Flame Retardant Rating | Size |

| ASTM D2240 (ASKER C) |

ASTM D3574 (kg/m³) |

ASTM D412 (MPa) |

ASTM D1056 (KPa) |

UL94 | mm | |

| NP-0815 | 10 ± 5 | 140 ± 30 | ≥ 0.3 | 20 - 50 | HBF | 1000 x 2000 |

| NP-1518 | 18 ± 5 | 150 ± 30 | ≥ 0.5 | 30 - 65 | HBF | 1000 x 2000 |

| NP-1820 | 20 ± 5 | 160 ± 30 | ≥ 0.6 | 35 - 65 | HBF | 1000 x 2000 |

| NP-1820F | 20 ± 5 | 160 ± 30 | ≥ 0.6 | 35 - 65 | V0 | 1000 x 2000 |

| NP-2530 | 30 ± 5 | 190 ± 30 | ≥ 0.8 | 50 - 100 | HBF | 1000 x 2000 |

| NP-2530F | 30 ± 5 | 190 ± 30 | ≥ 0.8 | 50 - 100 | V0 | 1000 x 2000 |

| NP-3035 | 35 ± 5 | 200 ± 30 | ≥ 0.8 | 60 - 120 | HBF | 1000 x 2000 |

| NP-4045 | 45 ± 10 | 300 ± 30 | ≥ 1.5 | 80 - 150 | V0 | 1000 x 2000 |

| NP-5565 | 55 - 70 | 230 ± 50 | ≥ 1.2 | 300 - 550 | V2 | 1000 x 2000 |

Explain: The above data are the results of internal laboratory tests and are for reference only. The physical properties of different batches of products are slightly different, and the actual situation shall prevail.

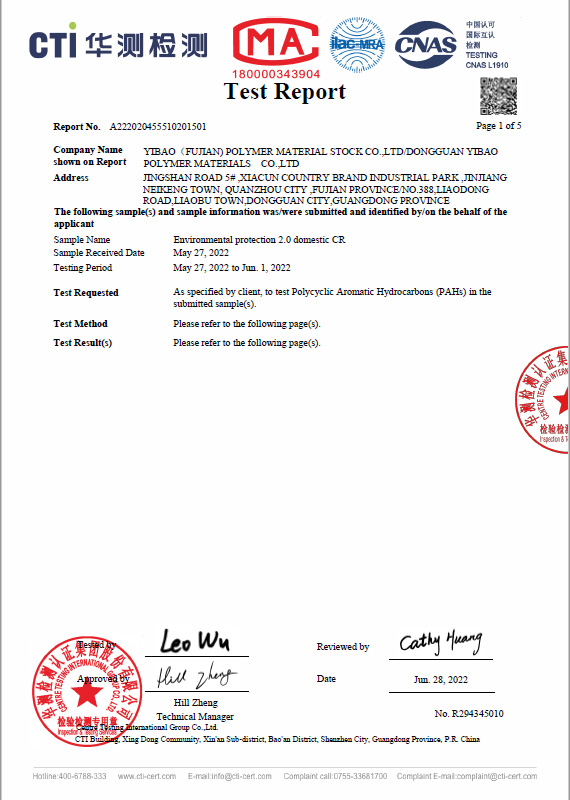

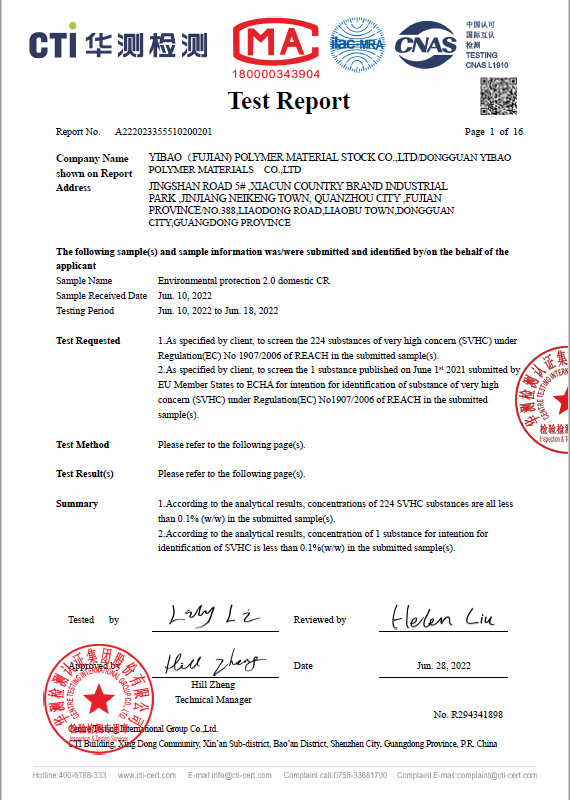

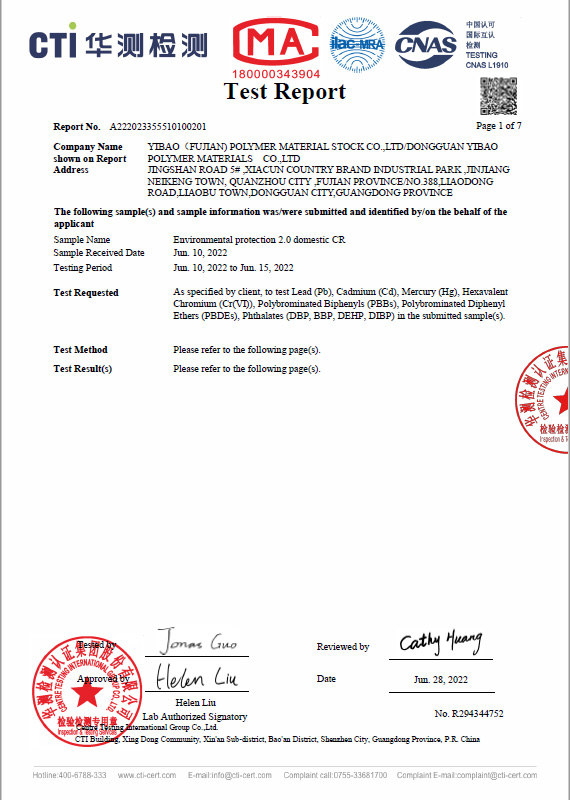

NBR & PVC Blend Foam Sponge CTI Test Report:

CTI PAHs Test Report

CTI REACH Test Report

CTI RoHS Test Report

Explain: Please contact sales representative for the complete test report.

NBR & PVC Blend Foam Sponge Can Fulfill The Below International Standards:

| PAHs | 15 substances (PAHs) for REACH Annex XVII Article 50 Amendment (Regulation (EC) No 1272/2013) |

| REACH (SVHC) | 224 + 1 Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 of REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |